Guaranteed consistent output, fast lead times, and competitive pricing for all your high-volume OEM projects.

Our Select Partners

Why Partner With Us

We deeply understand the stringent demands of secondary processing factories regarding capacity, quality consistency, and reliable delivery schedules. As your core supply chain partner, our advantage is rooted in three key pillars

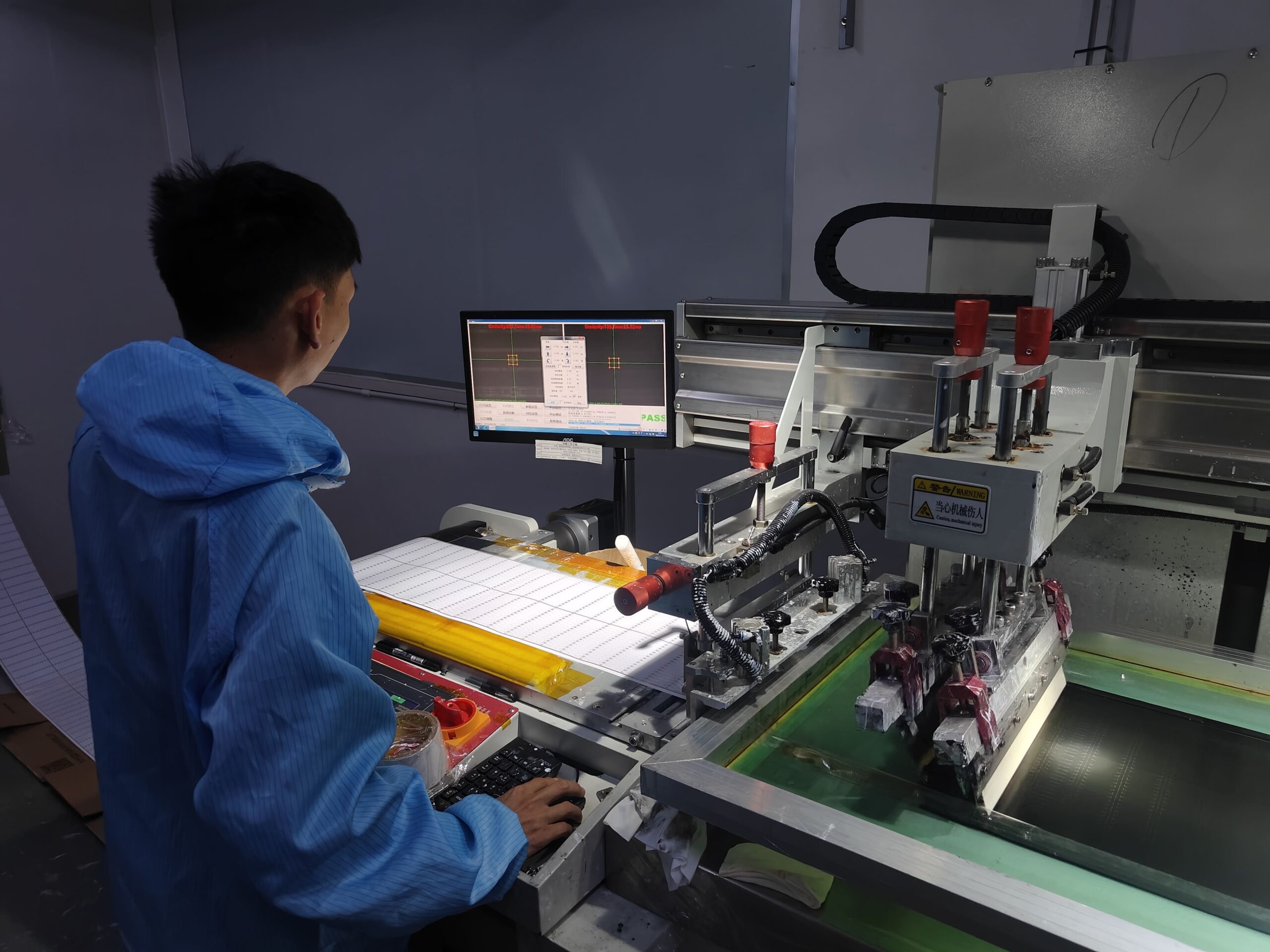

Scalability and Efficiency: The R2R Automation Guarantee

Technical Excellence: Consistency Beyond Industry Standards

Seamless Integration: Accelerating Your Time to Market

We leverage state-of-the-art Roll-to-Roll (R2R) fully automated surface-mount technology (SMT) processes. This ensures ultra-high precision and T-level production capacity, providing an unshakeable supply guarantee for all your high-volume OEM projects. We don’t just supply—we accelerate your assembly through optimized automation.

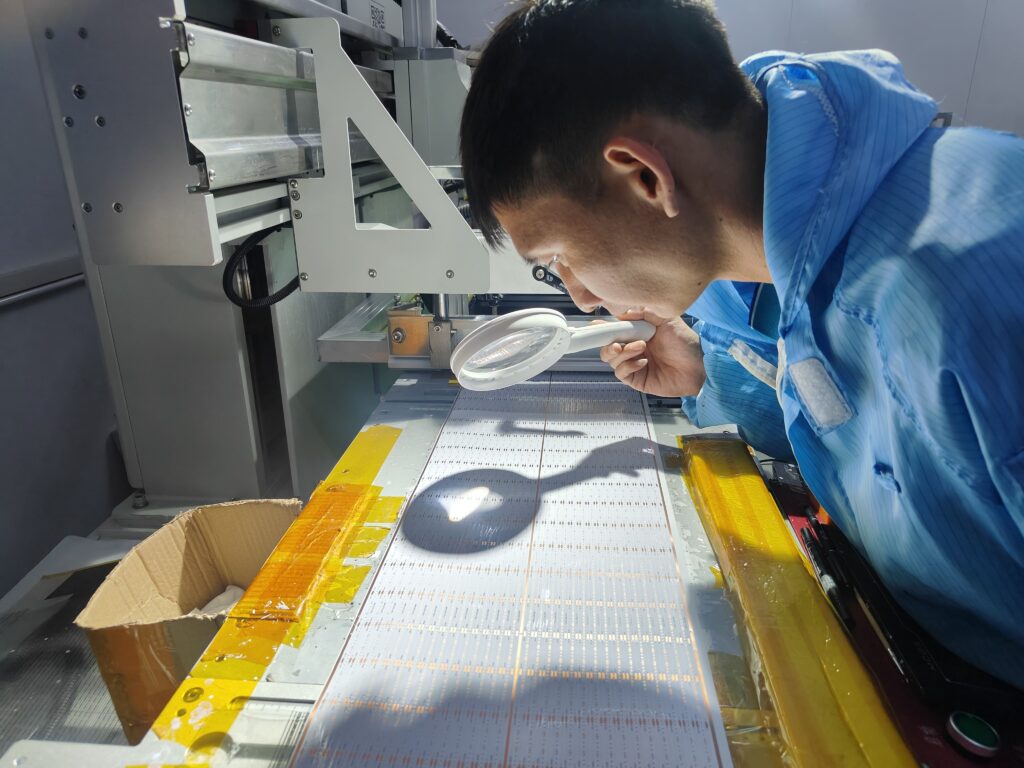

We implement a quality control system that exceeds typical industry benchmarks. Through rigorous precise binning and Constant Color Temperature (CCT) management, we guarantee 100% luminous color consistency across continuous batches for your end products. This proactive approach significantly minimizes your failure rates and quality risks.

Our dedicated technical team provides full-lifecycle support—from initial PCB design and power supply matching to custom length fabrication. We ensure that our LED modules integrate perfectly and seamlessly into your final assembly process, simplifying your production steps and expediting your time-to-market.

Supply Chain Solutions

Precision Customization & Prototyping

We offer tailored PCB and substrate design based on your final product housing and thermal management needs. Fast-track prototyping services guarantee component compatibility and reduce costly integration risks before mass production.

Technical Integration Consulting

Dedicated technical consultants assist your R&D teams with system integration, driver matching, and dimming protocol implementation (DALI, DMX, 0-10V). Ensure seamless functionality and optimized performance in the finished fixture.

Guaranteed Batch Consistency (Binning)

Implementation of strict MacAdam ellipse 3-step or tighter binning standards for CCT and CRI. This ensures guaranteed light color consistency across multiple batches and years of production, crucial for brand integrity.

Scalable Logistics & Inventory Management

Flexible fulfillment options, including JIT (Just-In-Time) delivery and managed buffer stock agreements. We adapt our logistics to match your production spikes and reduce your inventory holding costs.

Custom Silicone Extrusion for Linear Lighting

Our Silicone Neon Flex line is designed for manufacturers focusing on high-end architectural and exterior lighting fixtures. We utilize medical-grade silicone extrusion to ensure superior UV resistance, anti-yellowing performance, and extreme flexibility across a wide temperature range. The uniform dot-free diffusion is engineered specifically for seamless integration into linear profiles and creative designs, meeting stringent project requirements. Crucially, we provide custom profile extrusion and color matching services, ensuring the final encapsulated strip is perfectly tailored for your unique housing and installation environment, simplifying your assembly and guaranteeing product longevity.

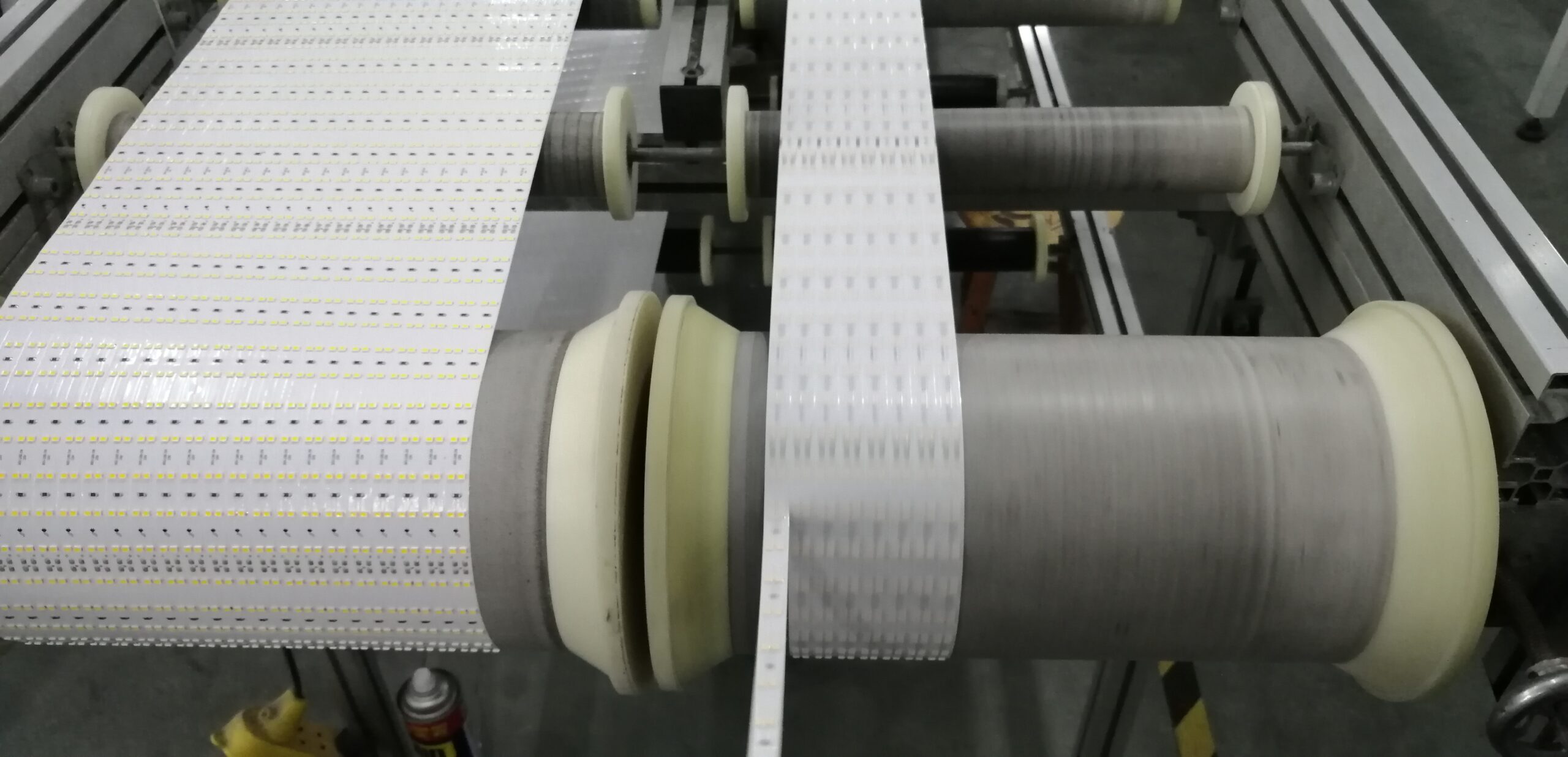

High-Volume Bare PCB Strip Manufacturing

Our bare LED strip production line is the bedrock of our commitment to excellence. Utilizing fully automated SMT technology and rigorous in-line inspection, we guarantee the superior quality of the foundational component your products depend on. We source premium components—from branded LED chips (LEDs) to high-conductivity flexible PCBs—ensuring exceptional thermal performance and longevity. This core capacity allows us to offer you the most cost-efficient and technically robust bare strips, ready for your subsequent waterproofing, sleeving, or profiling processes, guaranteeing optimal performance in your final fixture.

Why Work With Us

Global Compliance & Certification Support

We supply pre-certified components (UL, CE, RoHS compliant) with comprehensive documentation packages, ensuring your finished products pass global regulatory hurdles seamlessly. Our compliance simplifies your export process and reduces certification time-to-market risk.

Flexible Stocking & Inventory Management

Optimize your cash flow and floor space. We offer Vendor Managed Inventory (VMI) and Just-In-Time (JIT) delivery scheduling. This drastically reduces your warehousing costs and guarantees supply stability, even during peak demand periods.

Industry-Leading Commercial Warranty

Every LED strip component we supply is backed by an industry-leading 5-year commercial warranty. This commitment ensures predictable, long-term performance and acts as a direct quality assurance measure, protecting your brand reputation.

R&D Collaboration & Future-Proofing

Gain access to our R&D lab for joint testing and technical consultation. We actively collaborate on next-generation LED technologies (e.g., tunable white, new chip architectures), ensuring your product line remains competitive and ahead of market trends.

Client Testimonials

Ready to Scale Your Production with Confidence?

Contact our dedicated technical sales team today for a risk-free consultation. Whether you require tailored component design, complex system integration support, or competitive bulk pricing for your upcoming project, we are ready to engineer a robust supply solution that meets your exact specifications and timeline.