Engineering Trust: Our Foundation as Your Strategic LED Component Partner.

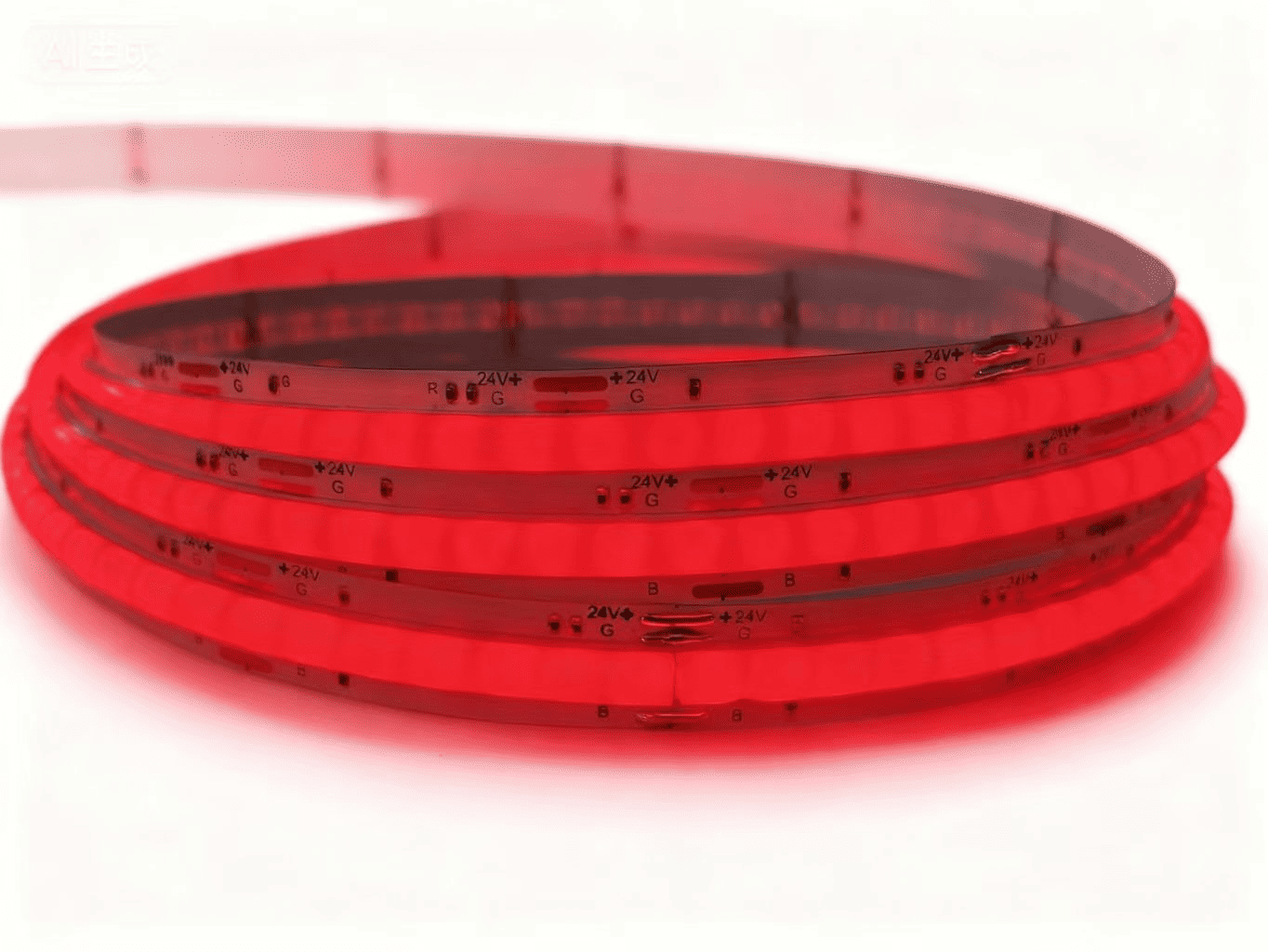

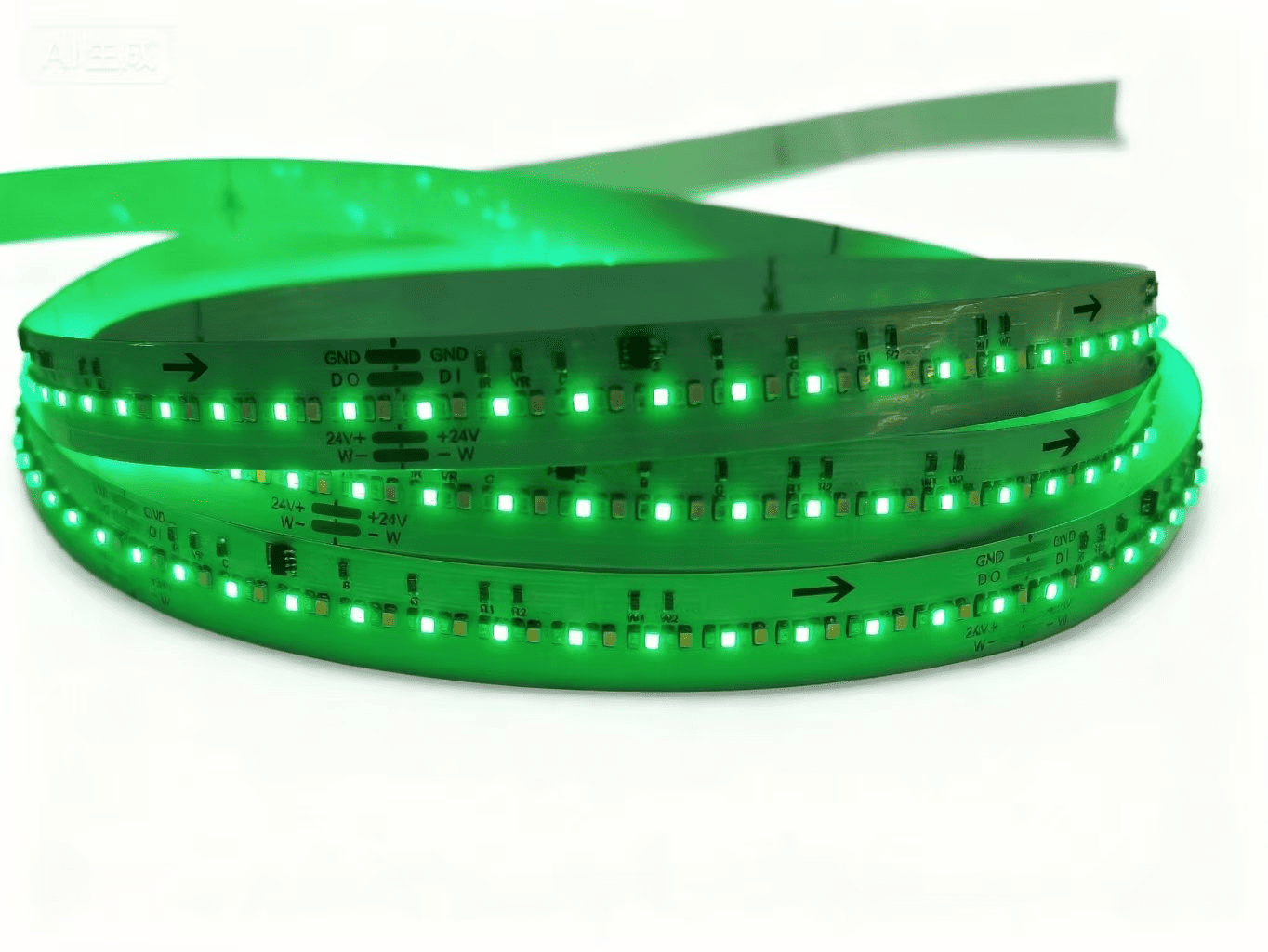

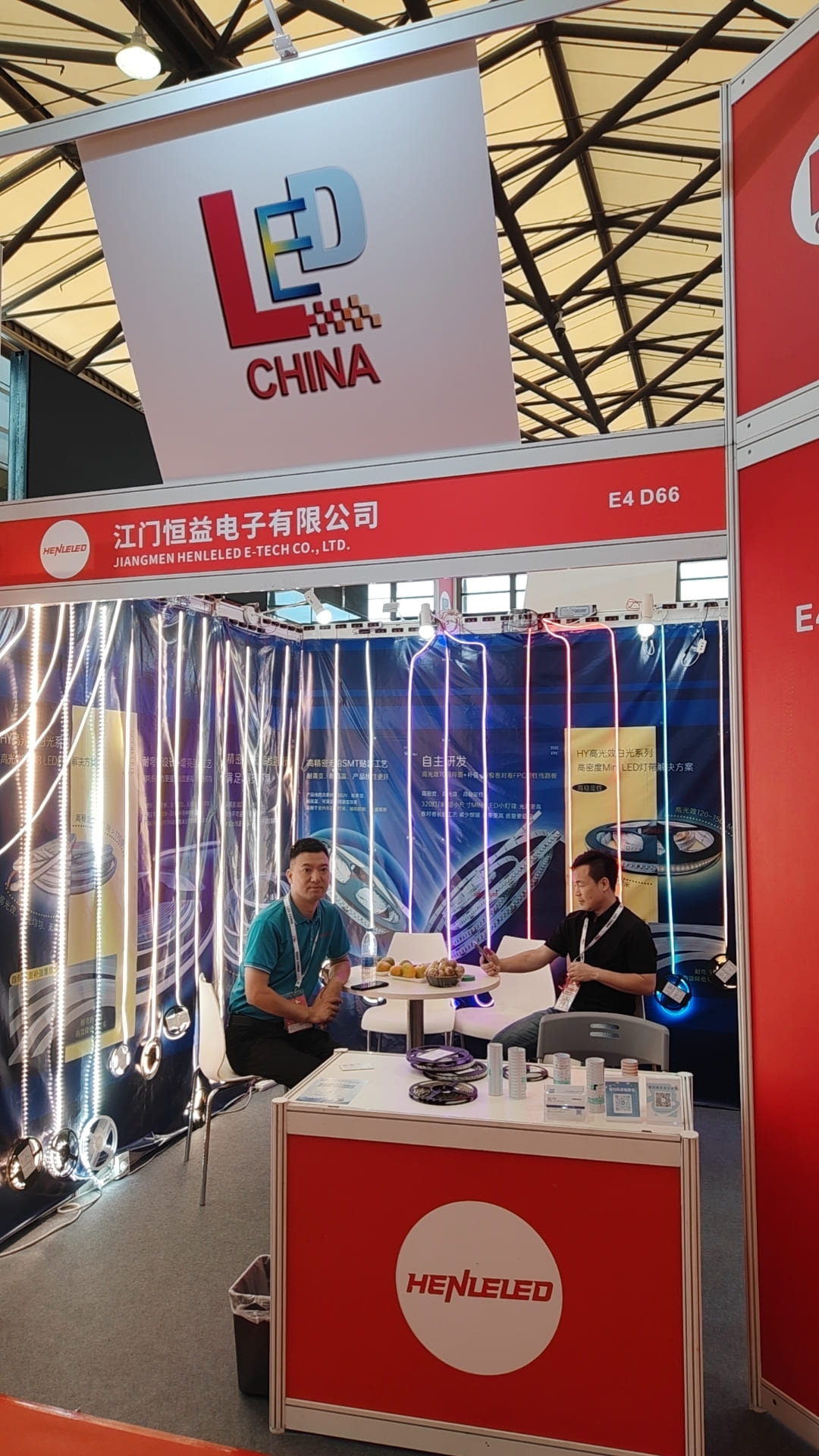

Since [2012], our mission has been to function as the essential manufacturing backbone for lighting fixture and component integrators globally. We specialize in high-precision, large-volume production of LED strip components, leveraging cutting-edge R&D and stringent quality assurance protocols. Our commitment extends beyond mere supply; we aim to be your strategic partner, ensuring the long-term consistency, innovation, and scalability required to keep your finished products ahead in a rapidly evolving market.

Our Vision:Redefining the Future of Precision LED Integration.

To be the globally recognized leader in flexible LED component manufacturing, driving the next generation of lighting innovation. We envision a future where our commitment to smart manufacturing, sustainable material science, and zero-tolerance consistency enables every manufacturing partner to dominate their respective markets. By continuously investing in R&D—particularly in areas like advanced optics, IoT compatibility, and enhanced thermal solutions—we ensure our clients always receive components that set new industry standards for efficiency, longevity, and predictable performance.

Our Core Values: The Principles That Drive Precision

Consistency First.

Engineering Integrity.

Focused Innovation.

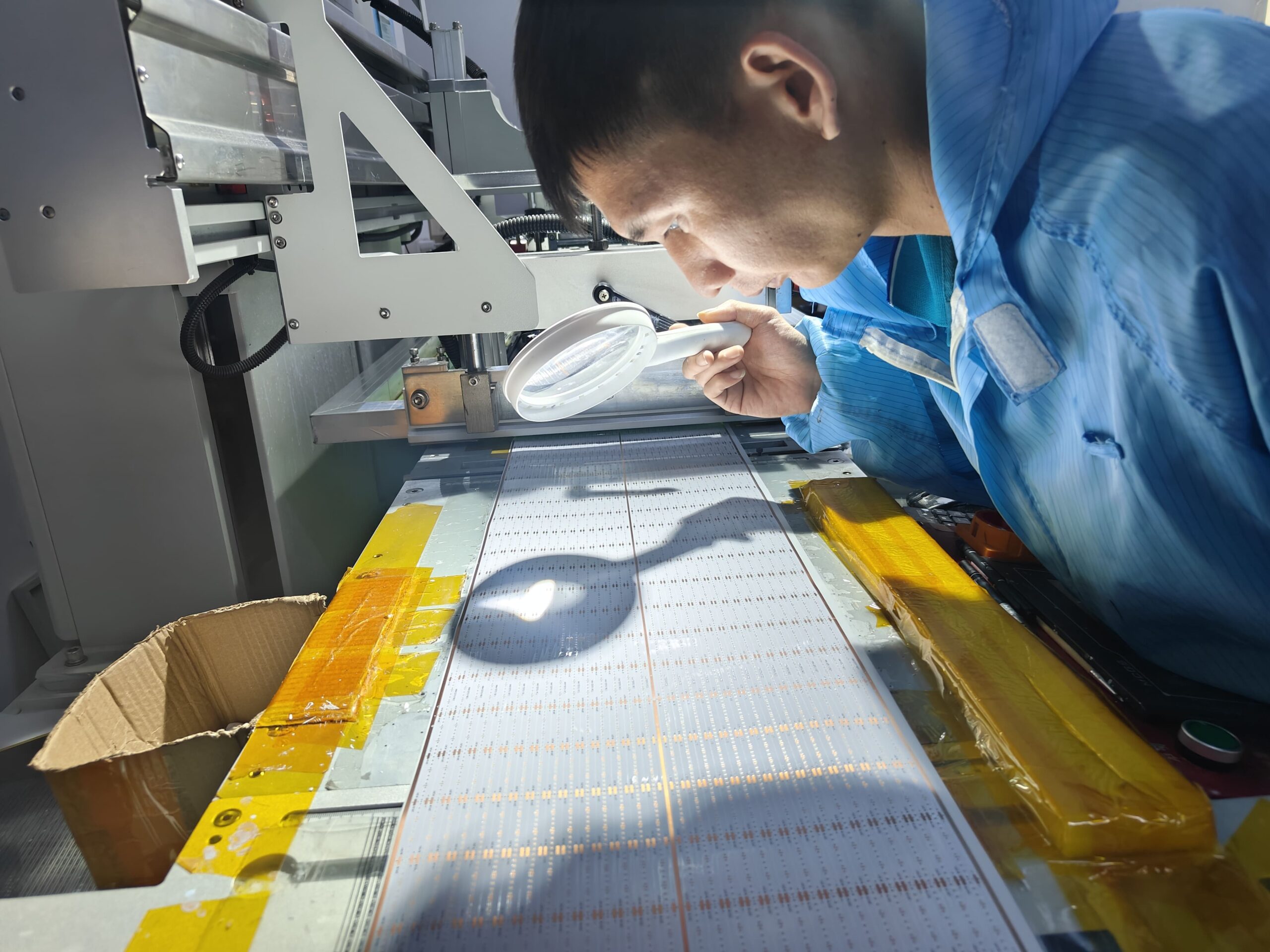

We maintain a zero-tolerance policy for deviation.

Our commitment is to technical truth and transparency.

We view R&D not as an expense, but as a commitment to your future market share.

History & Milestones

2012Company Foundation & Strategic Focus

—-Established as a specialized LED component supplier, driven by a commitment to rigorous quality control and market integrity.

2015Entry into Rigid PCB Production

—-Began high-volume SMT production of rigid LED PCB strips, marking our first major investment in automated manufacturing and building core competency in light source quality.

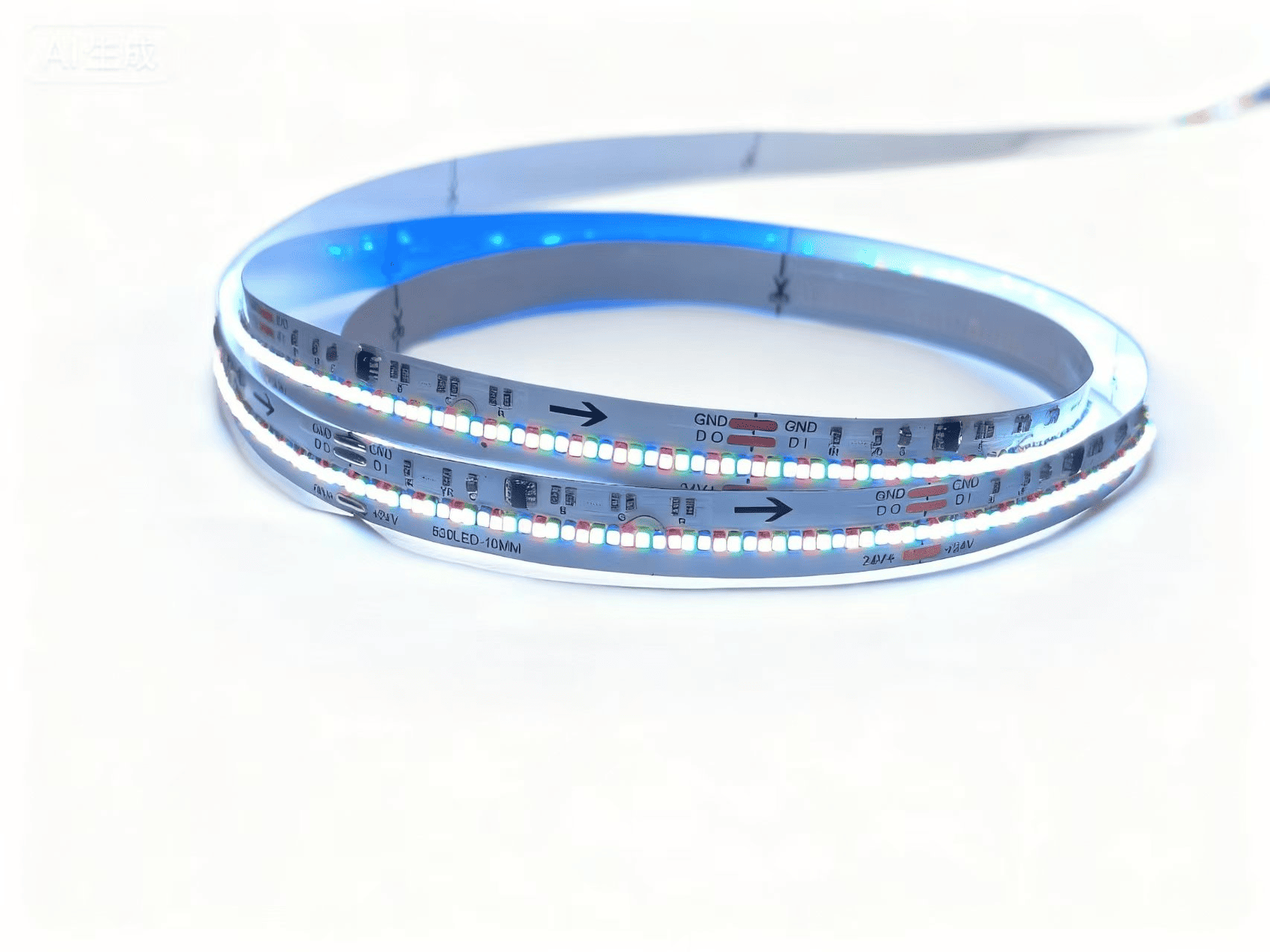

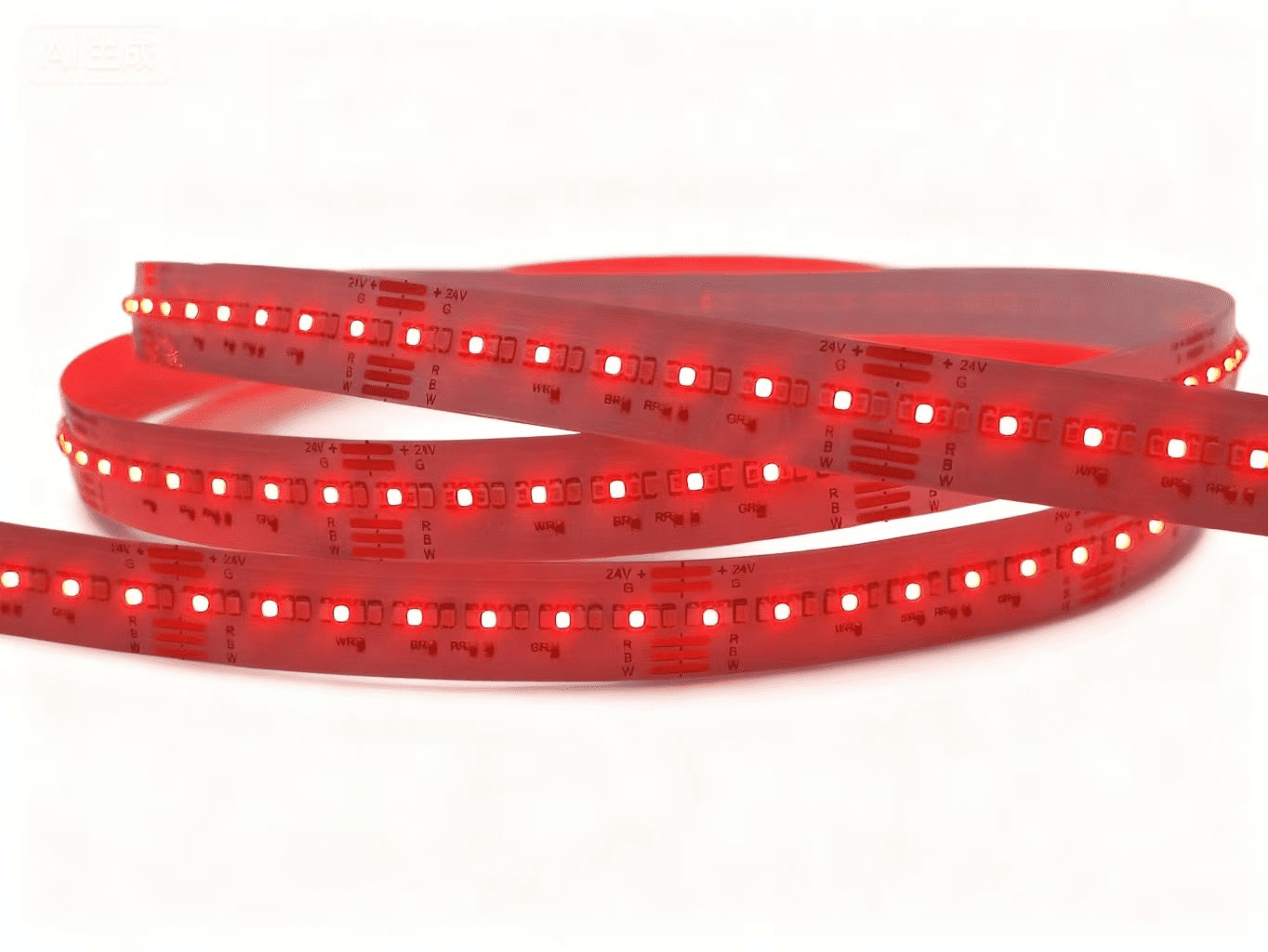

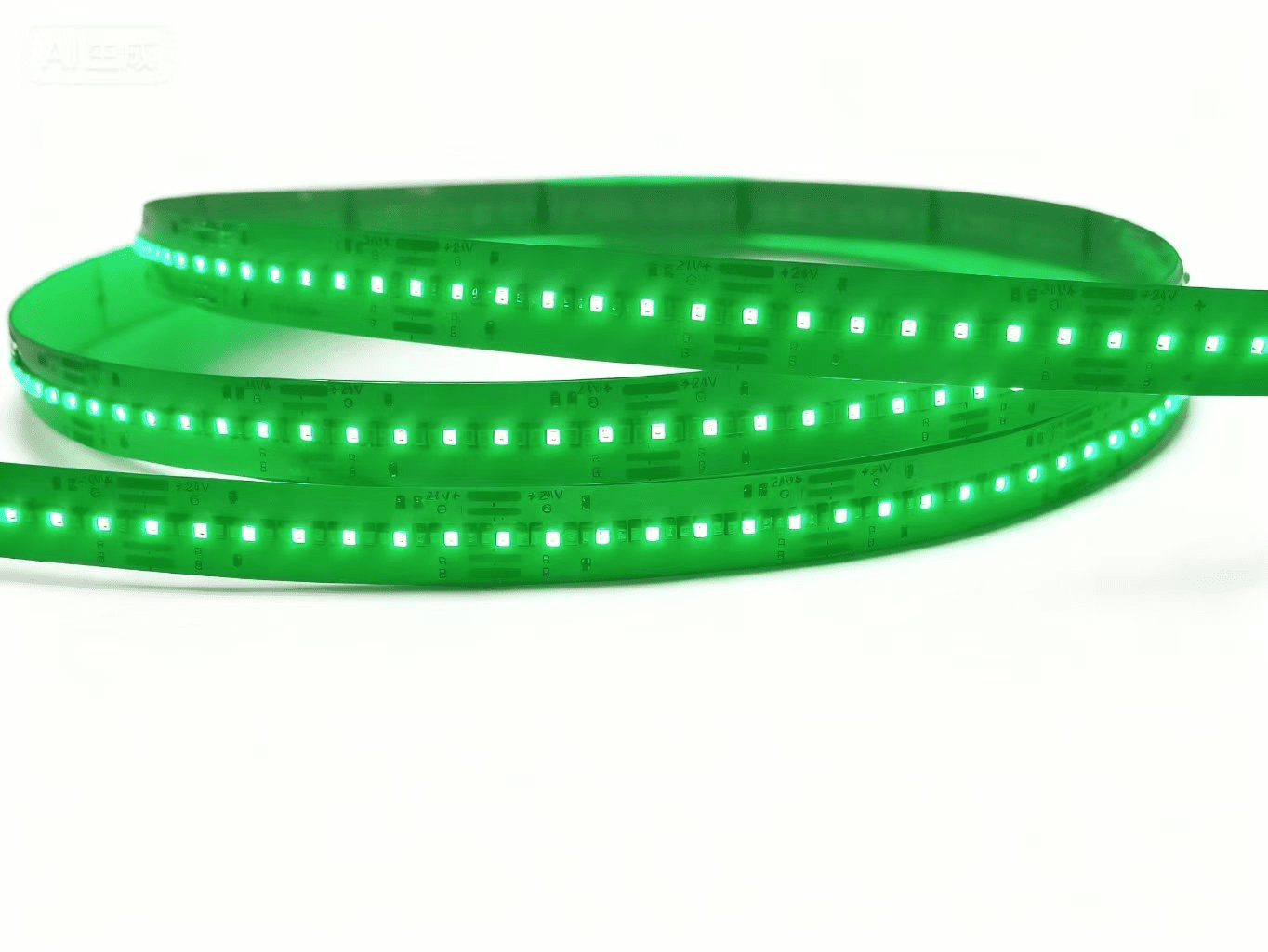

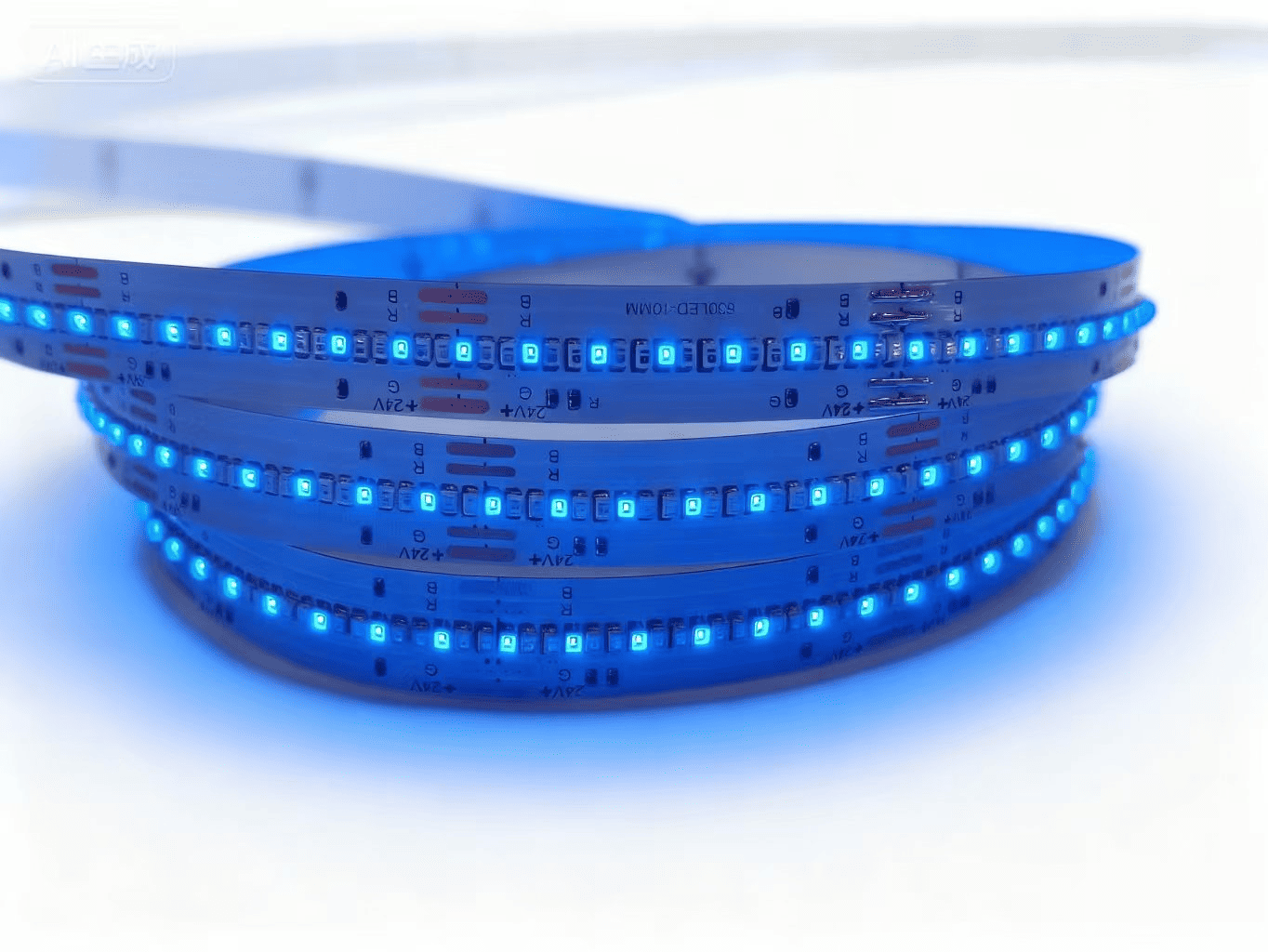

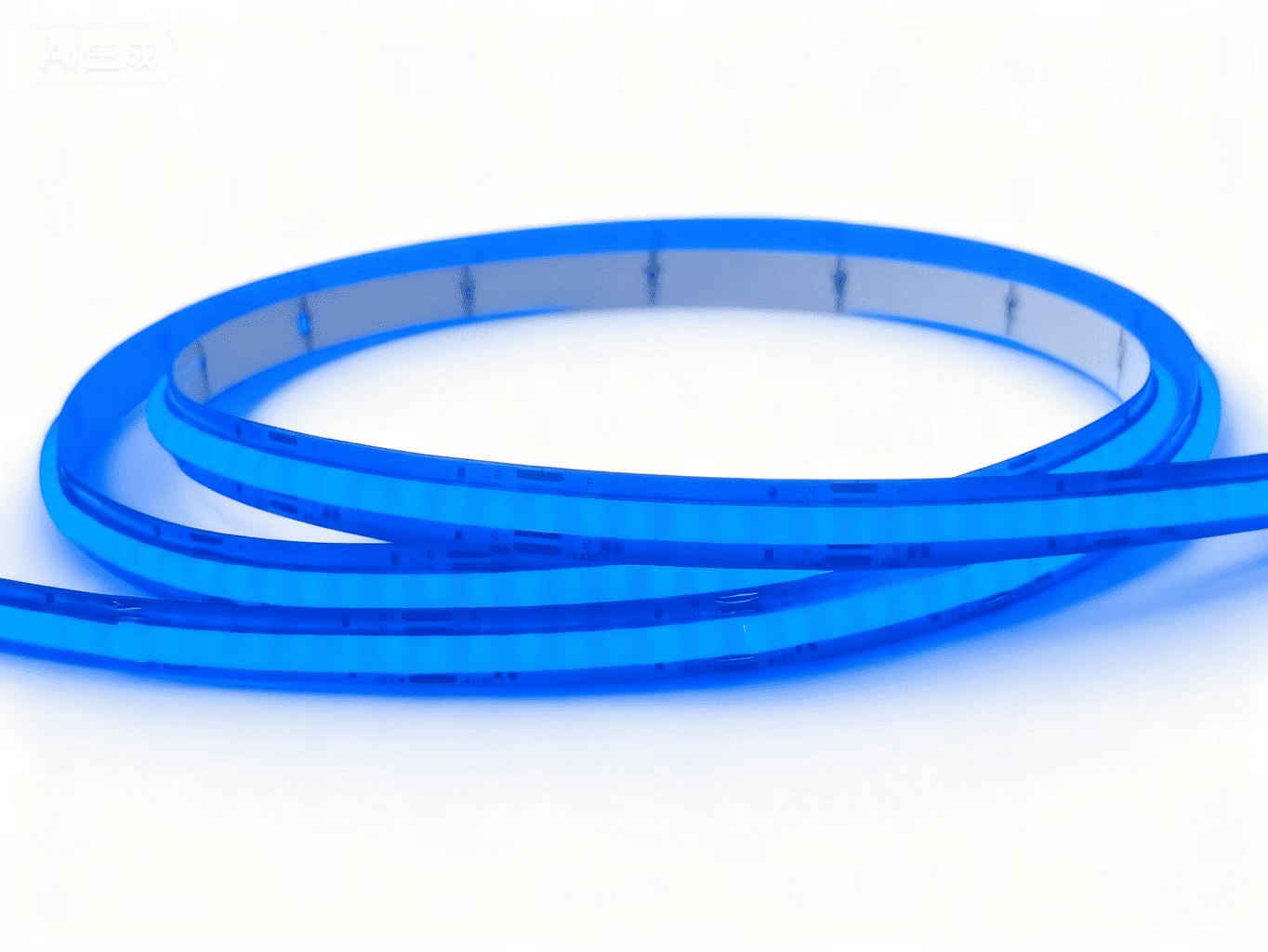

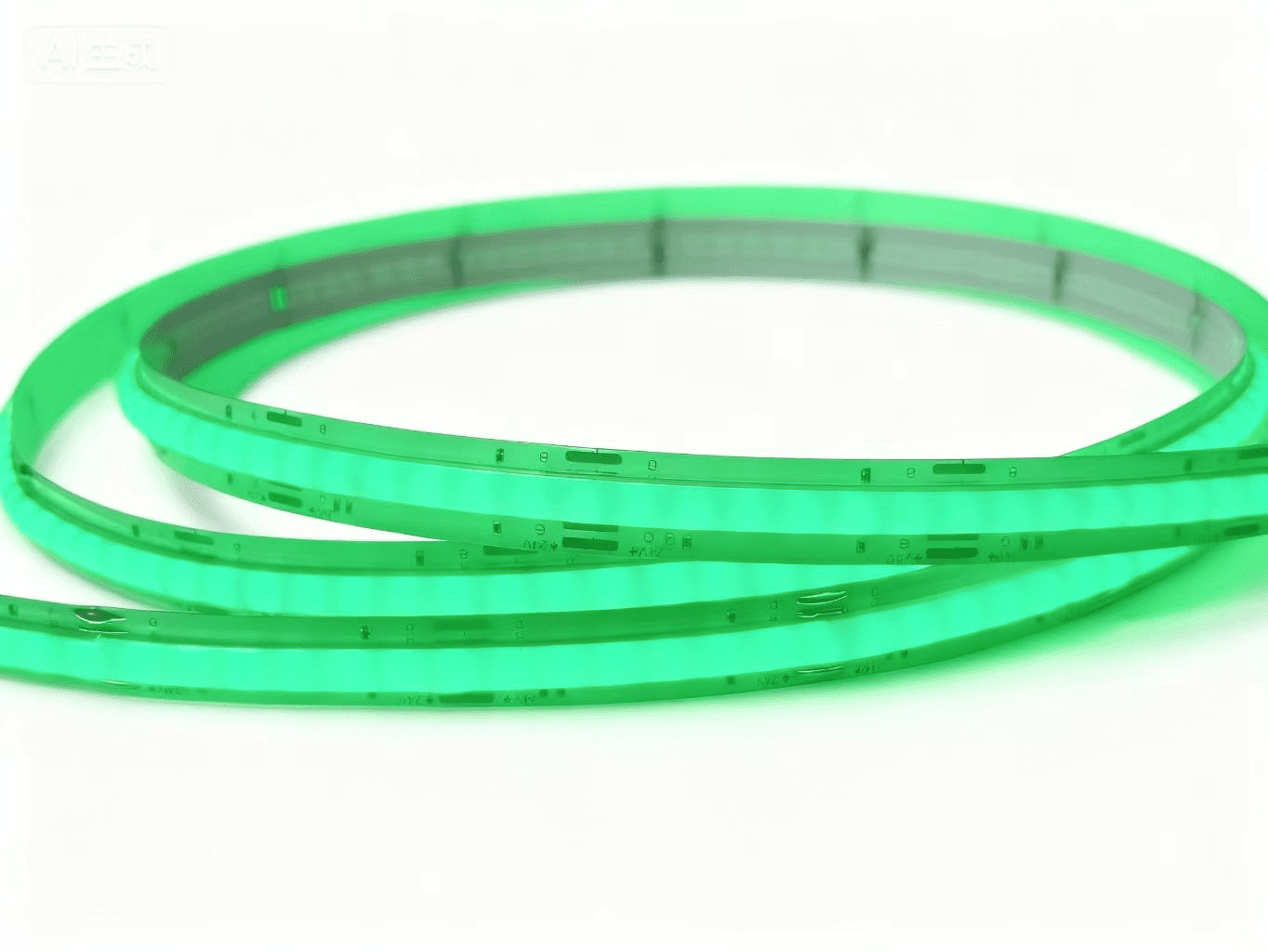

2020Flexible PCB Expansion

—-Expanded capabilities to include flexible strip production, serving the rapid growth in linear and custom lighting applications, requiring adaptability and high precision.

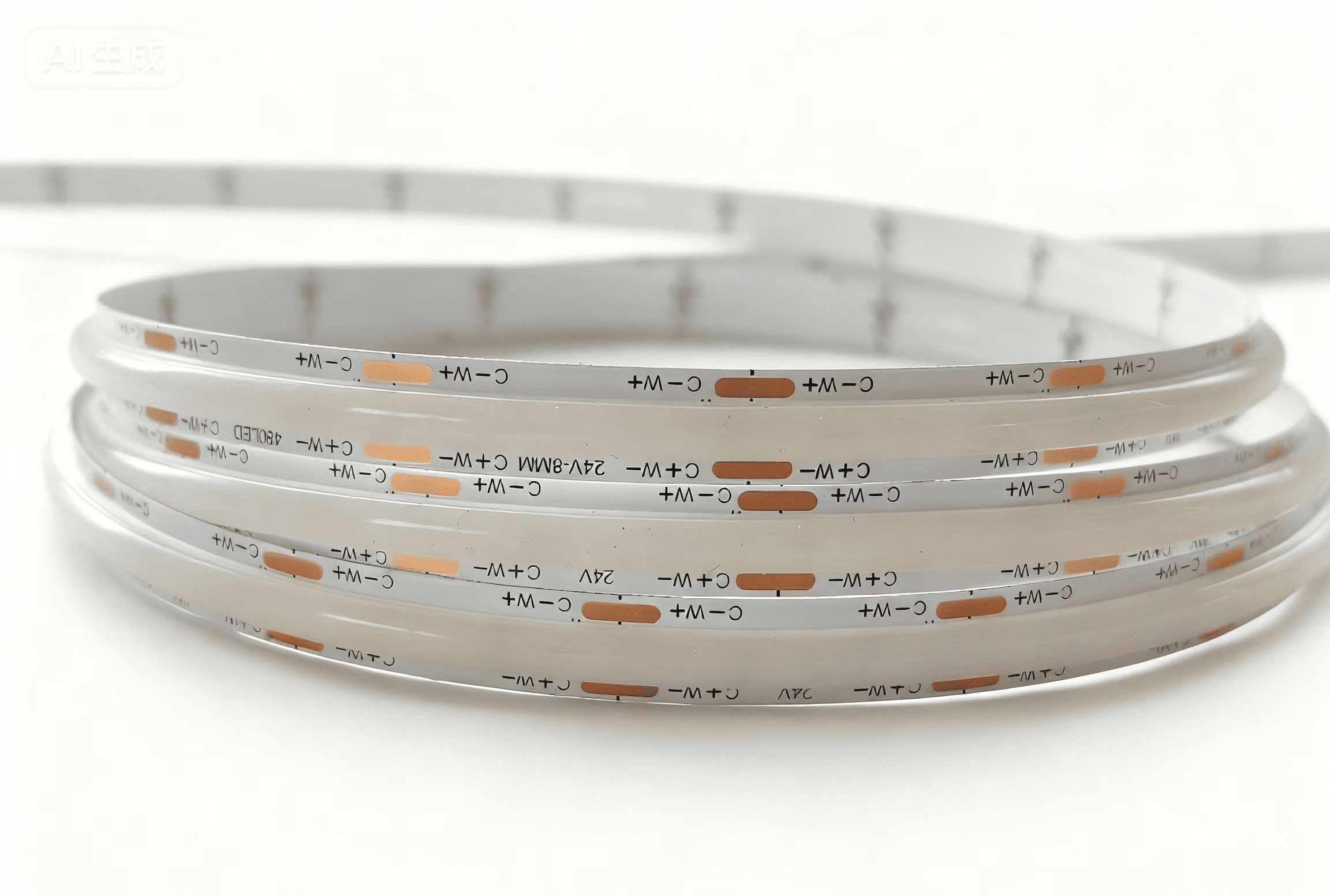

2023Next-Generation R2R Automation

—-Completed the implementation of advanced Roll-to-Roll (R2R) production lines, fundamentally shifting our capacity and cementing our status as a high-capacity, high-precision OEM component manufacturer.

Our Team

Eason Deng

International business manager

Wei Deng

Founder of the company

Yang Gong

Technican manager

Lily Wang

QC manager

Stop Guessing. Guarantee Batch Consistency with Precision LED Supply.

You cannot afford costly batch failures or supply chain interruptions.