For B2B professionals, understanding PCB copper thickness is not an engineering detail—it’s a critical safeguard against project failure. This parameter, more than almost any other, determines whether your installation will perform brilliantly for years or become a maintenance nightmare.

The Core Principle: Copper as a “Current Highway”

The copper traces on a flexible PCB are not just connectors; they are the electrical arteries of your LED strip. Their cross-sectional area (determined by thickness and width) defines their current-carrying capacity, following the fundamental relationship:

Resistance (R) = Resistivity (ρ) × Length (L) / Cross-sectional Area (A)

Thinner copper means higher resistance. This isn’t just a theoretical concern—it manifests in two catastrophic ways for lighting projects.

The Two Failure Modes Caused by Inadequate Copper

1. Voltage Drop: The “Dimming Tail” Phenomenon

This is the most visible and common failure. As current travels along a thin, high-resistance trace, energy is wasted as heat according to Joule’s Law (Power loss = I²R). This wasted energy causes a progressive voltage drop along the strip.

Consequence: LEDs toward the end of the run receive insufficient voltage. They become progressively dimmer, creating an uneven, unprofessional lighting effect that ruins architectural intent. In RGB/W strips, this can also cause color shifting at the far end.

A Practical Example:

A 5-meter run of high-density (60 LEDs/m) strips drawing 2A, on 1oz copper, can experience a voltage drop of up to 1.5V or more at the end. For a 12V system, this represents over 12% loss, causing noticeable dimming. The same run on 2oz copper might drop only 0.5V (4% loss), maintaining visual consistency.

2. Thermal Runaway: The Hidden Safety Hazard

The I²R power loss doesn’t just cause voltage drop—it generates heat. Thin copper traces become resistive heating elements. This heat:

- Accelerates LED degradation (as explained in the chip section)

- Damages the PCB substrate, potentially causing delamination

- Degrades solder joints, leading to intermittent connections or complete failure

- In extreme cases, can discolor or even ignite surrounding materials

Quantitative Analysis: Copper Thickness Specifications Decoded

Copper thickness is measured in ounces per square foot (oz), representing the weight of copper rolled to cover one square foot. Here’s what each specification means for your project:

| Copper Weight | Actual Thickness | Maximum Safe Current Density* | Professional Assessment |

|---|---|---|---|

| 1oz | ~35μm (0.0014″) | ~500 mA per 10mm trace width | Consumer-grade only. Acceptable for very short runs (<2m) of low-power decorative lighting where dimming at the end is tolerable. Marginally acceptable for indoor use. |

| 2oz | ~70μm (0.0028″) | ~1000 mA per 10mm trace width | The professional standard. Suitable for continuous runs up to 5-10 meters, depending on LED density. Maintains voltage integrity and thermal safety for most commercial applications. |

| 3oz+ | 105μm+ (0.0042″+) | ~1500+ mA per 10mm trace width | Industrial/heavy-duty grade. Essential for ultra-high-density strips, long continuous runs (>10m), or applications where absolute reliability is paramount (marine, cold storage, high-ambient-temperature environments). |

*Note: Current ratings depend on temperature rise allowances and trace width. These are conservative estimates for 20°C temperature rise.

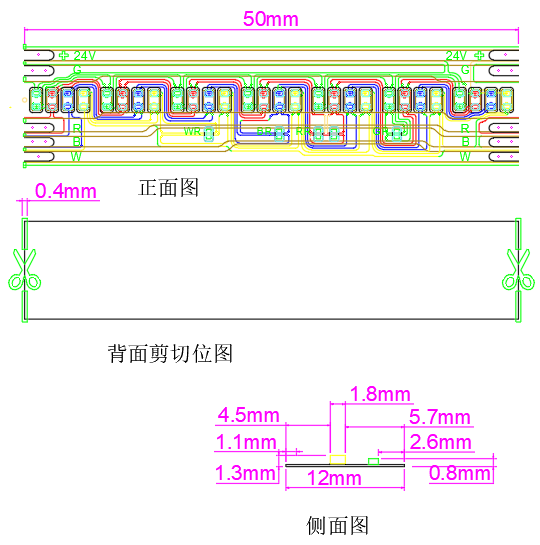

The Engineering Behind the Numbers: Trace Width Considerations

Copper thickness doesn’t work alone. The trace width multiplies its effect. The total cross-sectional area = thickness × width.

Example Calculation:

- A 1oz (35μm) copper trace, 2mm wide: Cross-section = 0.035mm × 2mm = 0.07 mm²

- A 2oz (70μm) copper trace, 2mm wide: Cross-section = 0.070mm × 2mm = 0.14 mm² (double the capacity)

Professional Insight: High-quality LED strips don’t just use thicker copper—they often widen the power traces at points of highest current, particularly at the beginning of the strip where all downstream current flows.

Real-World Testing Data: What We Measure in the Lab

Our validation testing reveals dramatic differences:

| Test Condition | 1oz PCB Result | 2oz PCB Result | Implication |

|---|---|---|---|

| 5m continuous run @ 72W load | Tail voltage: 10.3V (-14%) Max trace temp: +48°C above ambient | Tail voltage: 11.6V (-3.3%) Max trace temp: +22°C above ambient | 1oz铜箔导致显著压降和危险温升 |

| Accelerated aging (1000hrs @ max load) | Visible PCB discoloration Solder joint cracking observed | No visible degradation All solder joints intact | 1oz copper fails under sustained load |

| Voltage drop per meter @ 2A | ~0.3V/m | ~0.1V/m | For long runs, 1oz copper requires impractical power injection points |

The Cost-Benefit Analysis for B2B Decision Makers

The True Cost of Thin Copper:

- Additional Power Supplies: To combat voltage drop, you need more frequent power injection points, requiring additional drivers, wiring, and labor.

- Premature Failure: Early maintenance and replacement costs, including labor for hard-to-access installations.

- Warranty Claims: Product failures under warranty erode profitability.

- Reputational Damage: Failed lighting projects harm your brand as an installer/specifier.

Why 2oz Copper Pays for Itself:

- Enables longer continuous runs (fewer power supplies)

- Eliminates “dimming tail” callbacks

- Reduces thermal stress on LEDs (extending their lifespan)

- Provides safety margin for variable installation conditions

Specification Checklist for Professional Buyers

When evaluating LED strips, demand these verifications:

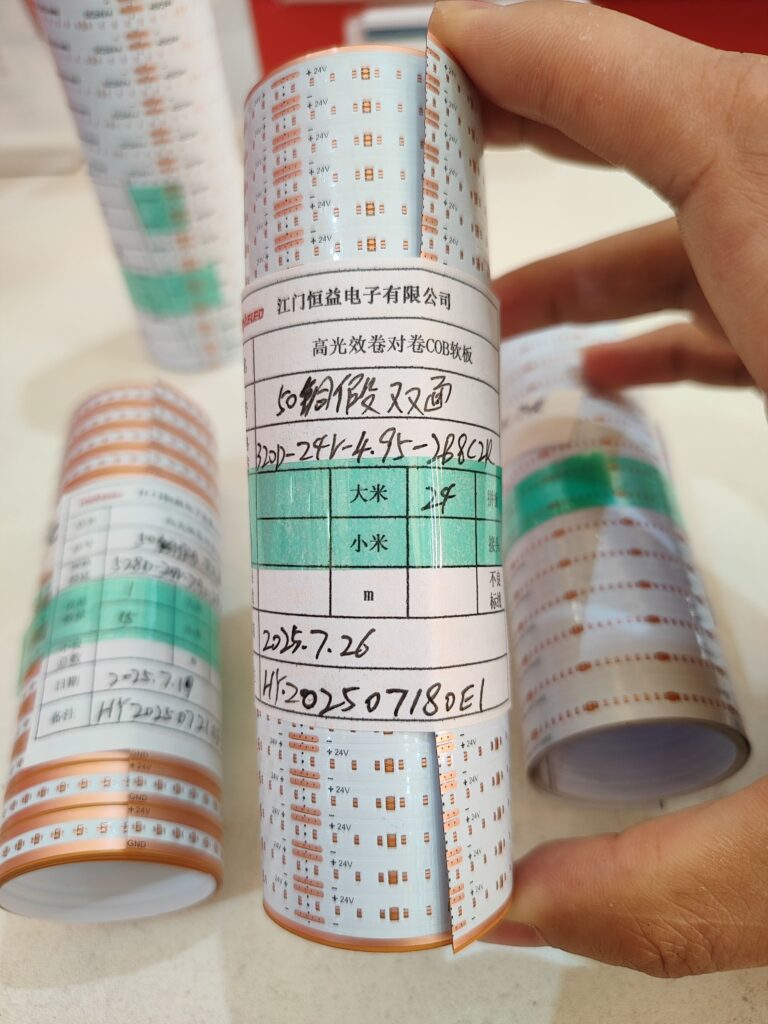

- Explicit copper weight specification in the datasheet (not just “heavy copper”)

- Voltage drop calculations for your intended run length and load

- Thermal imaging data showing maximum trace temperatures at rated load

- Trace width measurements at critical current points

- Third-party certification for safety standards (UL, IEC) which mandate sufficient current capacity

Questions to Ask Your Supplier:

- “What is the exact copper weight (in ounces) of your PCB?”

- “Can you provide voltage drop charts for 5m and 10m runs at full load?”

- “Do you use consistent copper thickness across all your product lines?”

- “What is the maximum recommended continuous run length without power injection?”

The Non-Negotiable Standard

For any commercial, architectural, or professional installation, 2oz copper should be the minimum acceptable standard. It represents the dividing line between consumer-grade products and professional lighting solutions.

The incremental material cost of thicker copper is insignificant compared to the total project cost, yet it provides disproportionate benefits in reliability, performance, and safety. When specifying LED strips, make copper thickness a non-negotiable requirement—it’s the foundation upon which all other performance characteristics depend.

In our next technical deep dive, we’ll examine how these electrical fundamentals interact with mechanical protection, exploring why the right waterproofing method must work in harmony with proper thermal management and current delivery.