Table of Contents

- The B2B Demand for Bespoke Lighting Solutions

- The Foundation of Flexibility: The Flexible PCB (FPC)

- 2.1 The Material Advantage: Copper Thickness and Durability

- 2.2 Roll-to-Roll (R2R) Manufacturing for FPC Precision

- Achieving Extreme Durability: The Silicone Neon Flex Solution

- 3.1 Superior Protection: Comparing Silicone vs. PVC/Epoxy

- 3.2 The Extrusion Process: Uniformity and IP Rating

- Beyond Linear: Custom Shapes and Dimensions

- 4.1 Custom Cut Lengths and Component Placement

- 4.2 Custom Dimensions and Profiles

- Partnering for Customization: From Concept to Production

1. The B2B Demand for Bespoke Lighting Solutions

In the competitive fields of architectural lighting, bespoke signage, and specialized vehicle lighting, standard 5-meter LED rolls are often inadequate. Projects frequently demand specific cut points, custom shapes, unique IP ratings, or specialized dimensions that require a manufacturer with deep control over the foundational components.

This is where the combination of High-Grade Flexible Printed Circuit Boards (FPC) and Advanced Silicone Extrusion Technology (Neon Flex) becomes essential. Understanding these manufacturing capabilities is the key to executing truly unique and high-performance projects.

2. The Foundation of Flexibility: The Flexible PCB (FPC)

The FPC is the core substrate of the LED strip, dictating its thermal performance, electrical reliability, and physical flexibility.

2.1 The Material Advantage: Copper Thickness and Durability

Low-quality FPCs use thin copper layers (often 1oz or less), which are prone to overheating, causing voltage drop and premature component failure.

- Solution: We insist on 2oz or 3oz rolled annealed (RA) copper FPCs. This thicker copper ensures superior heat dissipation and lower electrical resistance, which is critical for strip longevity, especially in high-power or challenging environments. The rolled annealed process enhances flexibility, reducing the risk of cracking during bending or installation.

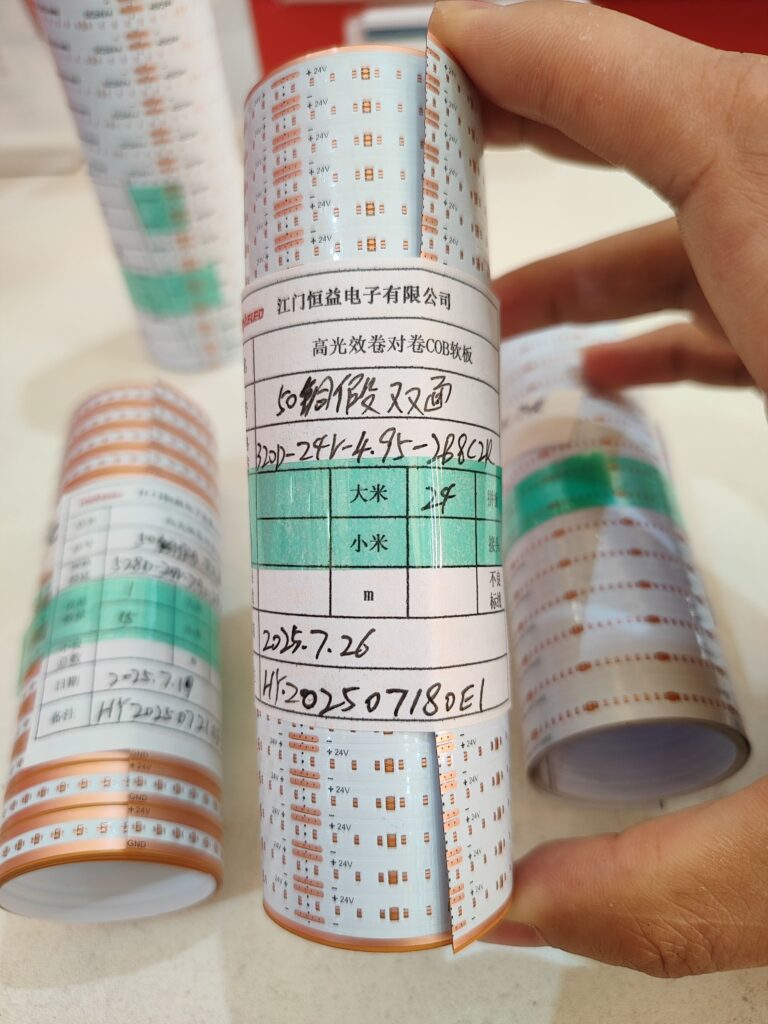

2.2 Roll-to-Roll (R2R) Manufacturing for FPC Precision

The only way to guarantee uniform material quality and precise alignment of component pads over long distances is through Roll-to-Roll (R2R) production.

- R2R Advantage: By processing the FPC material continuously from a large reel, we minimize material handling, eliminate tension variance, and ensure unparalleled dimensional stability during the subsequent SMT (Surface Mount Technology) phase. This provides the stable platform required for highly customized strips.

3. Achieving Extreme Durability: The Silicone Neon Flex Solution

For outdoor, damp, or harsh commercial environments, the protective layer is the primary defense against failure. Silicone Neon Flex offers vastly superior protection compared to traditional methods.

3.1 Superior Protection: Comparing Silicone vs. PVC/Epoxy

| Feature | Silicone Neon Flex (Extruded) | PVC or Epoxy (Potted/Coated) |

| UV Resistance | Excellent. Does not yellow, crack, or degrade under direct sunlight. | Poor. Prone to yellowing and becoming brittle over time. |

| Temperature Range | Extremely Wide (-40°C to +150°C). | Limited range; can stiffen in cold or soften in heat. |

| Flexibility | High, maintaining shape and integrity after repeated bending. | Lower flexibility; often prone to cracking the protective seal. |

| IP Rating Capability | Easily achieves IP67/IP68 rating through seamless extrusion. | IP rating relies on end-caps, which are common failure points. |

3.2 The Extrusion Process: Uniformity and IP Rating

High-quality silicone neon flex is created using an extrusion machine that continuously pushes the liquid silicone compound around the FPC strip.

- Online Curing: The freshly extruded strip immediately enters a tunnel oven for controlled curing. This controlled, continuous process ensures a seamless, hermetically sealed product with uniform wall thickness, achieving the high IP ratings essential for submerged or exposed applications.

4. Beyond Linear: Custom Shapes and Dimensions

Our commitment to FPC and extrusion technology allows us to move beyond standard product lines to meet your specific design needs.

4.1 Custom Cut Lengths and Component Placement

For integration into specific fixtures or signage, we can work with you to define non-standard cut lengths or custom placement of components (resistors, ICs, connectors) based on your schematic needs, saving significant labor during final assembly.

4.2 Custom Dimensions and Profiles

Need a neon flex profile that perfectly fits a unique architectural channel? We can develop:

- Custom Widths and Heights: To match existing specifications.

- Custom Extrusion Profiles: Such as curved tops, flattened sides, or specific mounting feet.

- Custom Color Silicone: Extrude the housing in a specific color (e.g., black, grey, or brand colors) before the LED is even lit.

5. Partnering for Customization: From Concept to Production

Choosing a manufacturer with deep FPC and extrusion expertise means you are not limited by off-the-shelf products. We provide the technical agility to realize complex lighting designs that demand precision, durability, and a unique form factor.

Do you have a project with custom requirements for IP rating, unique dimensions, or challenging installation environments? Share your technical drawings with us, and let us engineer a custom FPC and Silicone Neon Flex solution.

Pingback: The Ultimate LED Strip Power Supply Guide for B2B Lighting Projects - henleled.com