Table of Contents

- Why Quality Control in LED Strips is Non-Negotiable

- The Three Pillars of LED Strip Quality Failure

- 2.1 The Semiconductor: The Chip (LED Emitter)

- 2.2 The Circuit Board: The PCB

- 2.3 The Environment: Heat Dissipation and Protection

- Solutions for B2B Buyers: What to Demand from Your Supplier

- 3.1 Precision in Manufacturing (SMT & R2R)

- 3.2 Rigorous Component Sourcing

- 3.3 Advanced Testing and Validation

- Beyond the Standard: Choosing the Right LED for Your Project

- Partnering for Reliability: Your Solution Provider

1. Why Quality Control in LED Strips is Non-Negotiable

For B2B buyers in lighting, architecture, and manufacturing, the true cost of an LED strip is not the purchase price—it’s the cost of failure. Low-quality LED strips lead to premature dimming, color shifting, catastrophic failure, and expensive warranty claims and re-installation labor.

Your search for a supplier is driven by a critical need: reliability and consistency. This guide breaks down the key failure points in standard LED strip manufacturing and outlines the solutions your business needs to demand.

2. The Three Pillars of LED Strip Quality Failure

Failure in an LED strip usually originates from one of three areas. Understanding these points is crucial for informed procurement.

2.1 The Semiconductor: The Chip (LED Emitter)

The LED chip is the heart of the light source, and its quality dictates both performance and lifespan (L70/L80 ratings).

| Failure Point | Root Cause & Solution |

| Rapid Lumen Degradation | Cause: Use of low-grade or non-branded chips that cannot withstand operational heat. |

| Color Inconsistency (Binning) | Cause: Poorly sorted chips (wide CCT or CRI binning). |

| Solution: Demand chips from reputable brands (e.g., Osram, Cree, Samsung) with tight 2- or 3-step MacAdam ellipse binning (SDCM). |

2.2 The Circuit Board: The PCB

The Printed Circuit Board (PCB) is the backbone, responsible for electrical conductivity and heat transfer. Inflexible, thin, or poorly manufactured PCBs are a common source of failure.

- Copper Thickness: Thin copper layers (e.g., less than 2 oz) overheat easily, increasing resistance and shortening component life.

- Solution: Insist on 2oz or 3oz FPC (Flexible Printed Circuit) for high-power strips to ensure optimal current flow and heat management.

- Poor Solder Joints: Inaccurate Solder Paste Printing or inconsistent Reflow Soldering creates weak points that crack under thermal stress.

- Solution: Verify the supplier uses high-precision SMT (Surface Mount Technology) equipment with automated optical inspection (AOI).

2.3 The Environment: Heat Dissipation and Protection

Even a perfect chip on a perfect PCB will fail if the operating environment is not managed. This is where thermal management and protection layers come in.

- Inadequate Thermal Management: Excess heat is the enemy of LEDs. If the PCB cannot efficiently transfer heat away, the LED junction temperature rises, causing premature dimming.

- Solution: Utilize aluminum profiles or specialized thermal adhesives in installation. Demand suppliers specify the recommended heat sink for their high-power strips.

- Environmental Protection: For damp or outdoor applications, the protective coating is paramount.

- Failure: Cheap epoxy or thin silicone coatings crack, yellow, or fail to seal moisture.

- Solution: Opt for high-quality extruded silicone neon flex or PU (Polyurethane) coating for superior UV and water resistance (e.g., IP67/IP68 rated products).

3. Solutions for B2B Buyers: What to Demand from Your Supplier

To minimize risks, B2B procurement must vet a supplier based on their manufacturing process, not just their price list.

3.1 Precision in Manufacturing (SMT & R2R)

Look for suppliers who utilize state-of-the-art automation:

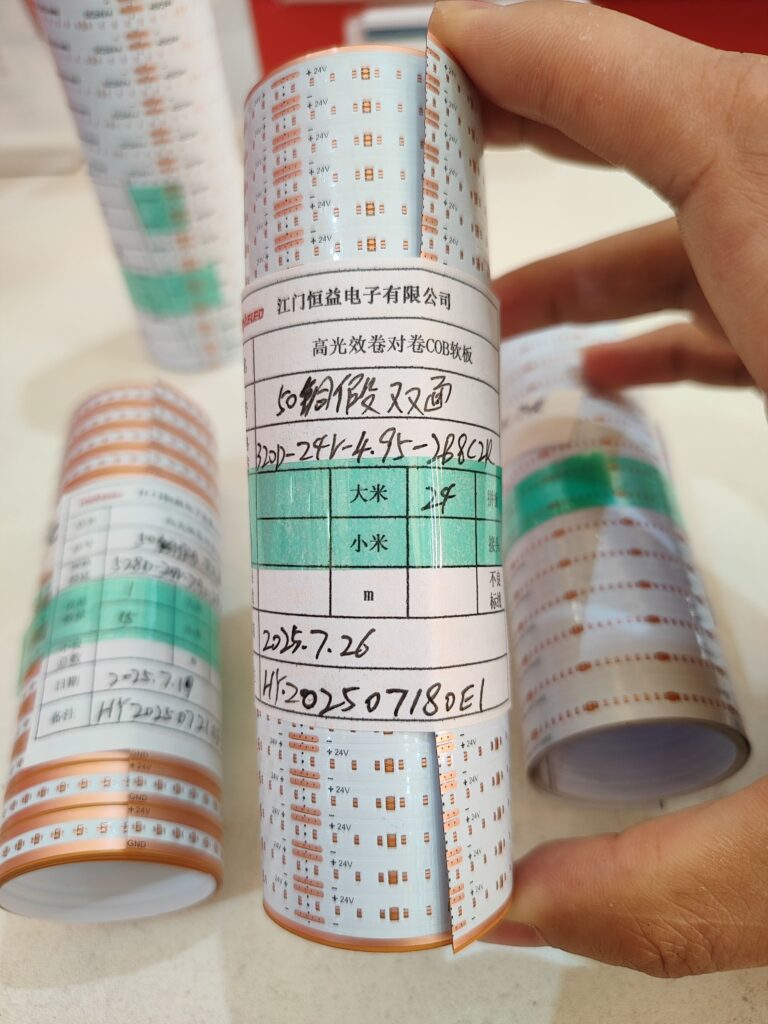

- Roll-to-Roll (R2R) PCB Production: This continuous process minimizes human handling and ensures consistent material tension and alignment, which is critical for flexible PCBs.

- Automated SMT Lines: High-speed pick-and-place machines ensure components are accurately placed. This must be followed by precise Solder Paste Printing and controlled Reflow Oven Temperature profiling.

3.2 Rigorous Component Sourcing

A reputable manufacturer will be transparent about their Bill of Materials (BOM):

- Branded Chips: As mentioned, specify chips from known, reliable suppliers.

- Quality Resistors and Components: Demand high-tolerance resistors and robust current regulators to maintain stable power flow, crucial for long life.

3.3 Advanced Testing and Validation

Quality assurance should go beyond a simple visual check. Demand to see evidence of:

- Integrating Sphere Testing: For accurate measurement of luminous flux, CCT, and CRI.

- Thermal Shock & Humidity Testing: To simulate real-world environmental stress.

- Aging/Burn-in Testing: Running finished strips in industrial ovens for hours to detect “infant mortality” failures before shipment.

4. Beyond the Standard: Choosing the Right LED for Your Project

High-quality manufacturing allows for advanced solutions tailored to specific B2B needs:

- Constant Current Strips: Ideal for long runs, these strips maintain consistent brightness throughout the length, eliminating voltage drop and reducing flicker.

- High-Density COB Strips: Offer a seamless, dot-free look, which is essential for premium architectural installations where aesthetics are critical.

- Custom CCT and CRI: Work with a supplier who can provide exact color temperatures and ultra-high CRI (CRI 95+) for applications like retail displays or photography lighting.

5. Partnering for Reliability: Your Solution Provider

Selecting an LED strip supplier should be a strategic decision. Your partner must demonstrate control over every stage: from raw material inspection and automated R2R production to rigorous quality checks and final product preparation (like precise slitting and re-reeling).

We don’t just supply LED strips; we supply lighting solutions engineered for longevity and consistent performance.

Are you currently evaluating suppliers for a new project? Let us help you review your component specifications to ensure maximum product lifespan and minimize failure rates.