IP Rating Demystified: How B2B Buyers Choose the Right Protection for LED Strips

Table of Contents

- The Hidden Risk of Choosing the Wrong IP Rating

- Decoding the IP Code: What the Numbers Mean

- Choosing the Right Level: From Indoor to Submerged

- 3.1 Basic Protection (IP20 – IP54)

- 3.2 Damp Environments (IP65)

- 3.3 Outdoor and Wash-Down (IP67)

- 3.4 Submerged and Extreme Conditions (IP68)

- Our Technology Advantage: Sealing Methods

- Minimize Project Risk: Your Next Step

1. The Hidden Risk of Choosing the Wrong IP Rating

Choosing the wrong IP (Ingress Protection) rating is a costly mistake. Water damage is the number one cause of outdoor LED strip failure.

For B2B buyers, project failure means expensive warranty claims. It means extra labor costs for replacement. You need a guarantee that your lighting will withstand the environment.

This guide simplifies the IP code. It helps you choose the exact protection level you need. We ensure your project stays reliable for years.

2. Decoding the IP Code: What the Numbers Mean

The IP rating is simple. It uses two digits: IP[X][Y].

- First Digit (X): Protects against Solids (like dust, fingers, tools).

- Scale: 0 (No protection) to 6 (Totally dust-tight).

- Second Digit (Y): Protects against Liquids (like drips, sprays, immersion).

- Scale: 0 (No protection) to 8 (Continuous immersion).

Focus on the second digit. This number is crucial for waterproof applications.

Need a quick reference chart? [Check out the official IEC standards for a complete breakdown of IP codes.] (External Link to Authority: IEC or a relevant standards organization blog)

3. Choosing the Right Level: From Indoor to Submerged

Different environments demand different protection methods. Do not over-specify protection. Do not under-specify protection.

3.1 Basic Protection (IP20 – IP54)

These are for dry indoor spaces. Think retail shelving or display cases.

- IP20: No special protection. Standard strip.

- IP54: Protected against dust ingress and light water spray. Good for dry, dusty factory areas.

3.2 Damp Environments (IP65)

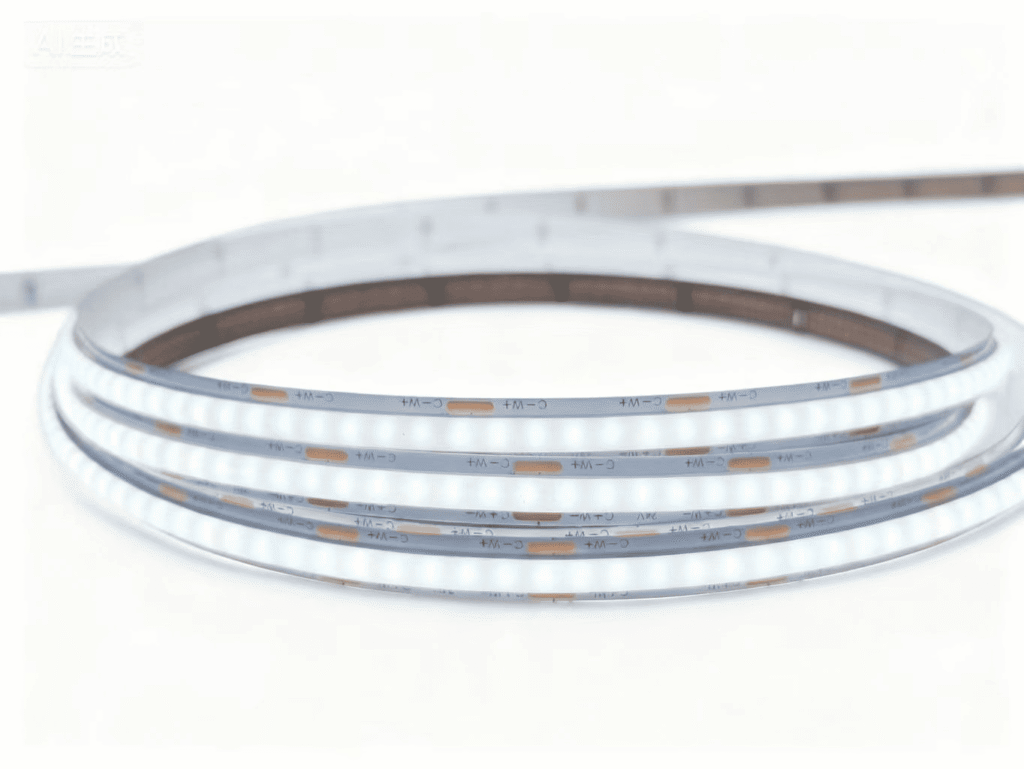

IP65 strips are protected against water jets from any direction.

- Best Use: Kitchens, bathrooms, or indoor areas prone to moisture (e.g., under eaves).

- Sealing Method: Usually protected by a thin silicone or epoxy coating.

3.3 Outdoor and Wash-Down (IP67)

IP67 strips can handle temporary immersion. This is a robust standard.

- Best Use: Outdoor facades, landscape lighting, or environments that need pressure washing.

- Key Feature: The strip is protected from dust and can be briefly submerged in water (up to 1 meter).

Explore our range of IP67 strips for facade lighting. [Visit our Waterproof Series Product Page onwww.henleled.com.] (Internal Link to Product Page: IP67/Outdoor Strips)

3.4 Submerged and Extreme Conditions (IP68)

IP68 is the highest rating. This is for constant, long-term immersion.

- Best Use: Pool lighting, fountains, marine environments, or harsh industrial settings.

- Sealing Method: Requires high-grade, fully sealed Silicone Extrusion or robust potting compounds. IP68 strips must be totally reliable.

4. Our Technology Advantage: Sealing Methods

The IP rating is only as good as the sealing method used. We do not rely on basic epoxy coatings that yellow or crack.

- Silicone Extrusion (For IP67/IP68): We use high-quality silicone. The strip is sealed seamlessly. This method offers superior UV resistance. It will not yellow over time. It prevents moisture ingress effectively.

- PU Glue Potting: For specialized needs, we use high-grade Polyurethane (PU) glue. This offers clearer optical transmission than standard epoxy.

We control the manufacturing process. This ensures every IP68 strip is perfectly sealed and tested. [Read our technical article on Silicone Neon Flex vs. Potted Strips.] (Internal Link to Previous Blog Post: Silicone Neon Flex Article)

5. Minimize Project Risk: Your Next Step

Do not guess your IP requirements. A small investment in the correct IP rating saves huge costs later.

Ready to select the perfect waterproof strip? We offer customized IP solutions for every environment.

Contact our technical sales team today. Let us help you match the ideal IP rating to your project environment. We guarantee your lighting will last.