LED Strip Voltage Drop Solutions are essential for any large-scale lighting project. If you have ever installed a long run of LEDs, you might have seen a problem. The lights at the start are bright. The lights at the end are dim. Sometimes, the color even changes. This is “voltage drop.” For a B2B professional, this is a major issue. It looks unprofessional and can lead to client complaints.

In this expert guide, we will explain why this happens. More importantly, we will provide the best LED Strip Voltage Drop Solutions to ensure your project looks perfect from start to finish.

Table of Contents

- What Exactly is LED Strip Voltage Drop?

- The Science: Why Voltage Drops Over Distance

- Visible Signs of Voltage Drop in Your Project

- The Impact of Voltage: 12V vs. 24V vs. 48V

- Professional LED Strip Voltage Drop Solutions: Power Injection

- Using Constant Current (CC) IC Technology

- The Role of Wire Gauge (AWG) in Voltage Management

- How PCB Quality Affects Electrical Resistance

- Calculating Voltage Drop: A Practical Formula

- Sourcing the Right Products at www.henleled.com

- Conclusion: Success Through Engineering

1. What Exactly is LED Strip Voltage Drop?

Before we talk about LED Strip Voltage Drop Solutions, we must define the problem. Voltage is like water pressure in a pipe. As water flows through a long pipe, friction slows it down. The pressure at the end is lower than at the start.

In an LED strip, electricity flows through copper traces on a PCB. Copper has resistance. As the electricity travels further, some energy is lost as heat. This loss is called “voltage drop.” By the time the electricity reaches the end of a 10-meter strip, there isn’t enough “pressure” left to light the LEDs at full brightness.

2. The Science: Why Voltage Drops Over Distance

Every electrical conductor has resistance. This is based on Ohm’s Law(V = I xR).

- V is Voltage.

- I is Current (Amps).

- R is Resistance.

In a long LED strip, the resistance (R) increases with length. If the resistance goes up, the voltage (V) available to the LEDs goes down. For B2B buyers, this is a critical calculation. If you use a thin PCB or low voltage, the resistance is higher. This makes the drop more severe.

3. Visible Signs of Voltage Drop in Your Project

How do you know if you need LED Strip Voltage Drop Solutions? Look for these three signs:

3.1 Uneven Brightness

This is the most common sign. The first three meters look great. The last two meters look dull. This ruins the “seamless” look of architectural lighting.

3.2 Color Shifting

LED chips need a specific voltage to produce the correct color. If the voltage drops too low, the blue light in a White LED might fade. This makes the end of the strip look yellow or pink. In RGB projects, the colors at the end will not match the colors at the start.

3.3 Excessive Heat

When energy is lost due to resistance, it turns into heat. A strip with high voltage drop often runs hotter at the beginning. This heat can damage the LED chips over time.

Are your lights underperforming? [Consult our technical team atwww.henleled.comfor a free system review.] (Internal Link)

4. The Impact of Voltage: 12V vs. 24V vs. 48V

One of the simplest LED Strip Voltage Drop Solutions is choosing a higher starting voltage.

- 12V Systems: These are common for cars or small DIY projects. However, they have the worst voltage drop. You can usually only run 5 meters before seeing a drop.

- 24V Systems: This is the B2B industry standard. By doubling the voltage, you cut the current (Amps) in half for the same power. Lower current means lower resistance loss. You can usually run 7 to 10 meters safely.

- 48V Systems: These are the ultimate LED Strip Voltage Drop Solutions for very long runs. You can often run 20 to 30 meters from a single power feed. This reduces the number of power supplies needed.

[Image comparing 12V, 24V and 48V LED strip run lengths]

5. Professional LED Strip Voltage Drop Solutions: Power Injection

Sometimes, you must use a specific strip that has a drop. In this case, “Power Injection” is the answer.

5.1 What is Power Injection?

Instead of only sending power into the start of the strip, you add extra wires. You connect these wires to the middle or the end of the strip.

5.2 Parallel Wiring

Think of it like a highway. If one road is blocked, you add a second road next to it. By running a separate 14AWG or 16AWG wire alongside the LED strip, you “inject” fresh voltage at the 5-meter or 10-meter mark. This is one of the most reliable LED Strip Voltage Drop Solutions for stadium or perimeter lighting.

6. Using Constant Current (CC) IC Technology

If you want to avoid extra wiring, you should look at Constant Current (CC) LED strips.

Standard strips use resistors. They are “Constant Voltage.” If the voltage drops, the light drops.

CC strips have tiny Integrated Circuits (ICs) on the PCB. These ICs regulate the current. Even if the input voltage drops from 24V to 19V, the IC ensures the LED chip receives the exact same current.

This is a premium product. It is one of the most effective LED Strip Voltage Drop Solutions because it handles the problem automatically. [See our Constant Current Series here.] (Internal Link to CC Product Page)

7. The Role of Wire Gauge (AWG) in Voltage Management

Many installers focus only on the LED strip. They forget the “extension wires” between the power supply and the strip.

If you use a thin wire (like 22AWG) over a long distance, the voltage will drop before it even reaches the LEDs.

- Solution: Use thicker wires. For most B2B projects, we recommend 16AWG or 14AWG for long lead wires.

- Check the chart: Always use an [online voltage drop calculator] (External Link to a tool like Southwire or a specialized LED calculator) before you buy your cable.

8. How PCB Quality Affects Electrical Resistance

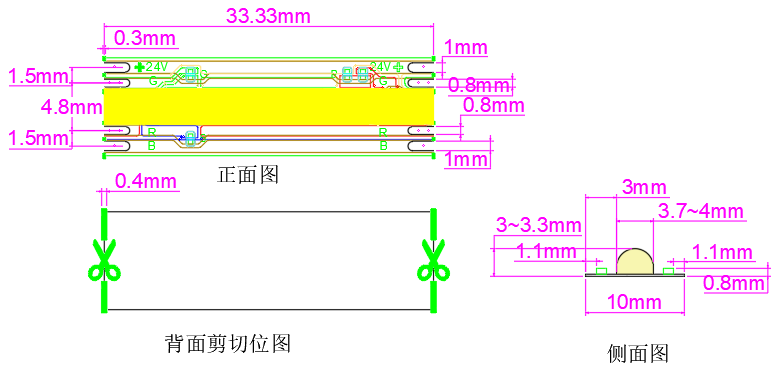

At Henle LED, we know that the PCB is the foundation of the strip. Not all PCBs are equal.

8.1 Copper Weight (Ounces)

Standard strips use 1oz copper. For high-power projects, this is not enough. We use 2oz or 3oz rolled copper. Thicker copper creates a wider “lane” for electricity. This significantly reduces resistance and is a core part of our LED Strip Voltage Drop Solutions.

8.2 PCB Width

A wider PCB (e.g., 10mm vs 8mm) can carry more current with less heat. When designing your project, always choose the widest PCB that fits your profile.

9. Calculating Voltage Drop: A Practical Formula

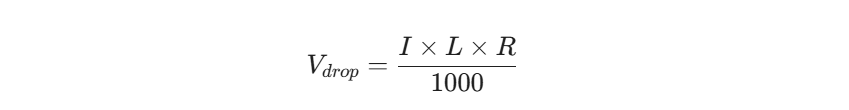

To find the right LED Strip Voltage Drop Solutions, you need to know the math. You can use the formula:

- Vdrop: The voltage lost.

- I: The current in Amps.

- L: The length in feet or meters.

- R: The resistance of the wire/PCB.

If the calculated V_{drop} is more than 10% of your total voltage (e.g., 2.4V drop on a 24V system), you must take action. You need thicker wire or a higher voltage system.

10. Sourcing the Right Products at www.henleled.com

Finding the right equipment is the final step. You need a partner who understands these engineering challenges.

At www.henleled.com, we provide:

- 48V Ultra-Long Run Strips: Perfect for 20m+ continuous lines.

- Constant Current IC Strips: For perfect brightness without extra wiring.

- High-Copper PCBs: Every strip we make is designed to minimize resistance.

We don’t just ship boxes. We help you design the power map for your project. This prevents “surprises” on the installation day.

Ready to buy? [Request a custom wiring diagram for your project today.] (Internal Link)

11. Conclusion: Success Through Engineering

Solving voltage drop is not magic. It is physics. By using the LED Strip Voltage Drop Solutions we discussed—higher voltage, power injection, and quality PCBs—you can achieve a flawless installation.

Remember, a professional B2B lighting project is judged by its consistency. Don’t let dim ends ruin your reputation. Invest in the right technology and the right partner.

Do you have a challenging project? Contact the experts at www.henleled.com. We have the experience and the products to solve any voltage drop issue. Let’s build something bright together!