Table of Contents

- Why Color Quality is Crucial in High-End Applications

- 1.1 The Impact of Poor Color Rendering

- Understanding the Metrics of Quality Light

- 2.1 Color Rendering Index (CRI) and R-Values

- 2.2 TM-30-15: The Modern Standard

- The Hidden Secret: Tight Binning (MacAdam Ellipses)

- 3.1 What is Binning and Why It Matters

- 3.2 Achieving Color Consistency Across Batches

- Manufacturing Commitment: How We Guarantee Fidelity

- 4.1 Precision Testing (Integrating Sphere)

- 4.2 Strict Component Sourcing

- Selecting the Right High-Fidelity Strip for Your Project

1. Why Color Quality is Crucial in High-End Applications

In sectors like luxury retail, art galleries, high-end hospitality, and film production, lighting is not just functional—it is a critical design tool. In these environments, the fidelity of the light directly impacts the perceived quality and true color of the illuminated objects (merchandise, artwork, food, and skin tones).

Using low-quality LED strips can lead to catastrophic visual results:

1.1 The Impact of Poor Color Rendering

- Retail: Products look dull, colors appear faded, and sales conversion rates suffer.

- Museums/Galleries: Artwork colors are misrepresented, distorting the artist’s intent and potentially damaging delicate materials.

- Hospitality: Food looks unappetizing (due to lack of strong R9 red light), and skin tones appear unnatural or sickly.

For professional buyers, understanding the technical specifications that guarantee superior color quality is paramount.

2. Understanding the Metrics of Quality Light

To move beyond generic LED claims, B2B buyers must analyze specific photometric metrics.

2.1 Color Rendering Index (CRI) and R-Values

CRI (Color Rendering Index) measures how faithfully a light source reveals the colors of various objects compared to natural light.

- The Standard: A minimum CRI of Ra 80 is common. For high-end applications, you must demand Ra 90 or Ra 95+.

- The Flaw (R9): The standard Ra metric is calculated using the first eight color samples (R1-R8). It often ignores R9 (saturated red), which is crucial for making reds vibrant and enhancing skin tones and food presentation.

- Solution: Always demand high R9 values. A truly high-quality strip will have a CRI 90+ and an R9 value above 50, ideally 80+.

2.2 TM-30-15: The Modern Standard

While CRI is useful, the IES TM-30-15 is a modern, comprehensive standard that offers a more holistic view of color quality using two metrics:

- $R_f$ (Fidelity Index): Similar to CRI, measuring color accuracy (100 is perfect).

- $R_g$ (Gamut Index): Measures the saturation of colors (above 100 means colors are slightly more saturated; below 100 means colors are desaturated).

Demanding suppliers provide TM-30 data demonstrates a commitment to the highest standard of color quality.

3. The Hidden Secret: Tight Binning (MacAdam Ellipses)

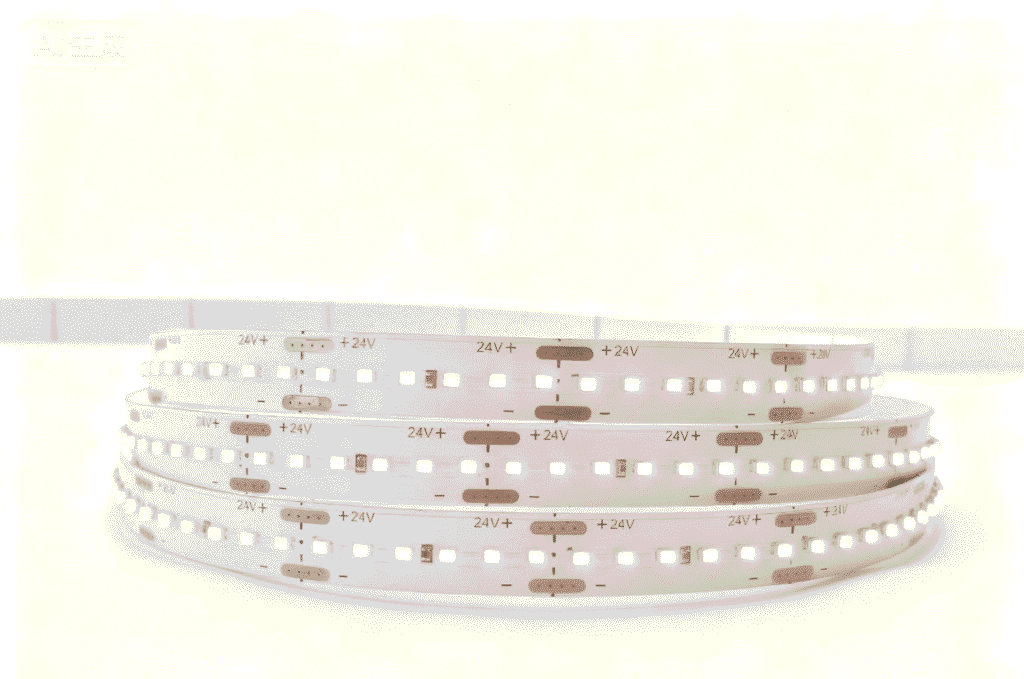

Even if you specify CRI 95 chips, if the chips are not consistently sorted, the color temperature (CCT) will vary visibly across the entire installation. This inconsistency is known as Color Binning.

3.1 What is Binning and Why It Matters

LED chips are produced in batches, and due to manufacturing variances, they output slightly different CCTs and intensities. Binning is the process of sorting these chips into specific groups (bins) based on their actual light output properties.

- MacAdam Ellipse: This is the industry standard for measuring the acceptable deviation in color. The human eye can barely perceive a color difference within a 1-step MacAdam ellipse.

- Consumer Grade: Typically uses 5- to 7-step binning, which results in clearly visible color shifts from roll to roll or strip to strip.

- Professional/Architectural Grade: Requires 2-step or 3-step MacAdam ellipse binning to ensure absolute color consistency.

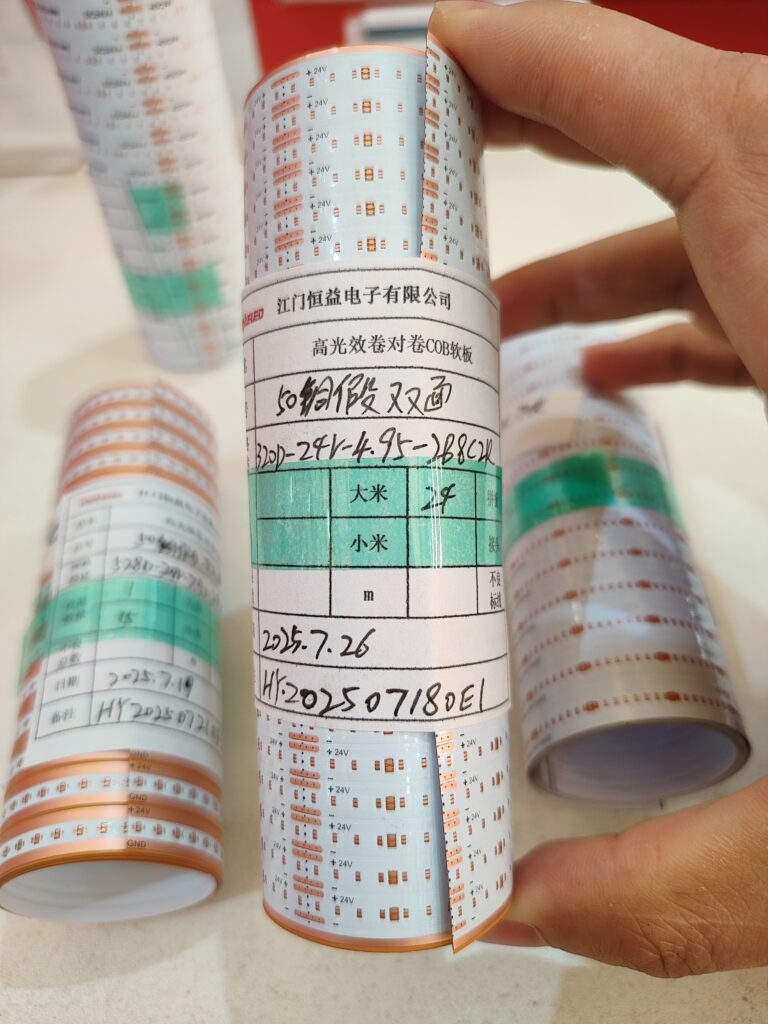

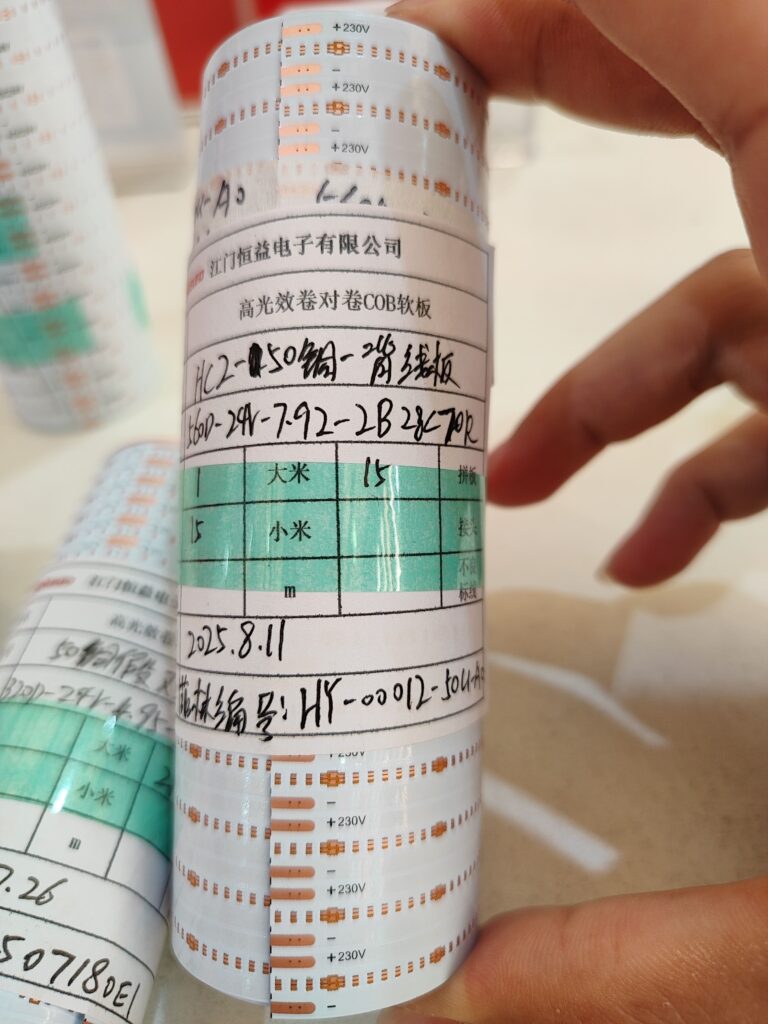

3.2 Achieving Color Consistency Across Batches

For large projects requiring thousands of meters installed over several months, color consistency between different batches is critical. A manufacturer must:

- Only purchase chips that fall within the tightest MacAdam bins.

- Maintain rigorous inventory control to track and match bins across production runs.

4. Manufacturing Commitment: How We Guarantee Fidelity

Guaranteeing color quality is a commitment that starts with component selection and ends with rigorous testing.

4.1 Precision Testing (Integrating Sphere)

We utilize an Integrating Sphere for every batch of finished product. This advanced photometric testing equipment accurately measures the precise CRI, R-Values, $R_f$, $R_g$, and CCT of the LED strip, providing verifiable data for our clients.

4.2 Strict Component Sourcing

We maintain strong partnerships with top-tier global LED chip manufacturers (e.g., Osram, Samsung, Nichia) to ensure access to their premium, tightly binned chips with high R9 values. We never substitute components based on cost savings.

5. Selecting the Right High-Fidelity Strip for Your Project

When specifying LED strips for premium environments, insist on the following verifiable data points:

- CRI: Ra 90+ (Ideally Ra 95+)

- R9 Value: 80+

- Color Consistency: 3-Step MacAdam Ellipse (or tighter)

- Verification: Integrating Sphere Test Reports

Our commitment is to eliminate the risk of poor color rendering and visible color inconsistency from your projects. We deliver light that enhances, not detracts, from the environment you create.

Do you require high CRI LED strips for a specialized art installation or a premium retail rollout? Contact our lighting experts to discuss verifiable color fidelity specifications.

Pingback: High CRI LED Strip Lights: The Ultimate Guide to Color Quality for B2B Buyers - henleled.com