Table of Contents

- The Hidden Cost of Voltage Drop in Large-Scale LED Projects

- CV vs. CC: Understanding the Core Differences

- 2.1 Constant Voltage (CV): The Limitation

- 2.2 Constant Current (CC): The Solution

- How CC Technology Eliminates Brightness Inconsistency

- Key Technical Benefits of Choosing CC Strips

- 4.1 Maintaining Uniform Luminosity

- 4.2 Extended Run Lengths and Simplified Installation

- 4.3 Enhanced Longevity and Efficiency

- When to Specify Constant Current Strips

- Partner with the CC Experts for Flawless Execution

1. The Hidden Cost of Voltage Drop in Large-Scale LED Projects

In large architectural, commercial, or display lighting projects, standard LED strips often encounter a critical technical challenge: Voltage Drop.

Voltage drop occurs when the electrical resistance within the copper traces of the PCB causes the voltage to decrease over the length of the strip. The result is unacceptable for professional projects:

- Visible Dimming: The light strip appears noticeably dimmer at the far end compared to the start.

- Color Shift: Lower voltage can subtly affect the LED chip’s performance, leading to slight color or CCT variations.

- Inefficient Use of Power: The project fails to deliver uniform, professional lighting, leading to rework and client dissatisfaction.

For B2B buyers, addressing this issue requires moving beyond basic Constant Voltage (CV) technology and adopting a superior technical solution: Constant Current (CC) LED Strips.

2. CV vs. CC: Understanding the Core Differences

The key to preventing voltage drop lies in how the strip manages power delivery to the individual LED chips.

2.1 Constant Voltage (CV): The Limitation

Standard LED strips are Constant Voltage (CV) driven (typically 12V or 24V).

- How it Works: The power supply provides a fixed voltage. The strip uses basic resistors to limit the current flowing to the LED chips.

- The Problem: As the input voltage drops along the strip due to resistance, the current supplied to the final LEDs also drops significantly. This causes the dimming effect. The resistors are passive and cannot compensate for this drop.

2.2 Constant Current (CC): The Solution

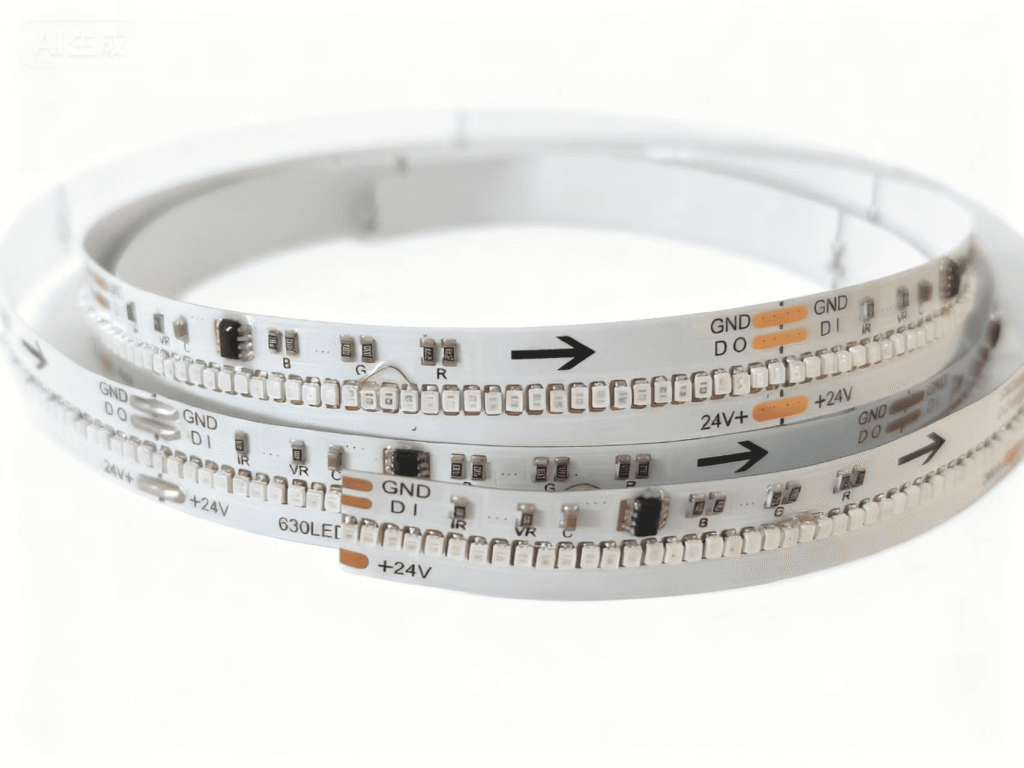

Constant Current (CC) LED strips integrate sophisticated regulating circuits (often small integrated circuits or ICs) along the PCB.

- How it Works: The primary power supply still provides a higher voltage (e.g., 24V or 48V). However, the embedded CC circuits actively monitor and regulate the current delivered to each LED section to a constant, precise level, regardless of minor voltage fluctuations along the strip’s path.

- The Benefit: By fixing the current, the output (brightness and color) remains perfectly uniform from the first meter to the last.

3. How CC Technology Eliminates Brightness Inconsistency

Imagine a water hose (representing the current).

In a CV system, the water pressure (voltage) drops, and therefore, the water flow (current) drops, making the spray weaker at the end.

In a CC system, the internal regulators act like mini-pumps placed along the hose. Even if the main pressure drops slightly, these pumps ensure the water flow rate to each nozzle remains exactly the same, resulting in uniform spray strength (brightness).

This active regulation is what makes CC strips the only viable solution for professional installations requiring long, continuous, and uniformly lit lines.

4. Key Technical Benefits of Choosing CC Strips

4.1 Maintaining Uniform Luminosity

CC strips ensure a zero tolerance for noticeable dimming, guaranteeing that the light output at the final cut point matches the light output at the power feed point. This is non-negotiable for high-end architectural and retail projects where aesthetic consistency is paramount.

4.2 Extended Run Lengths and Simplified Installation

Because CC technology compensates for resistance, these strips can be run significantly longer than standard CV strips before requiring a new power feed.

- Example: A standard 24V CV strip might be limited to 5 meters, while a high-quality 48V CC strip can often run 10, 15, or even 20 meters seamlessly from a single feed.

- Benefit: Fewer power supplies, fewer connection points, and dramatically simplified installation labor, leading to substantial cost savings on site.

4.3 Enhanced Longevity and Efficiency

By actively controlling the current, CC drivers prevent overcurrent conditions that can damage LED chips.

- Temperature Control: Stable current results in more stable junction temperatures for the LED chips.

- Increased Lifespan: This stable environment significantly contributes to the LED’s L70 lifespan rating, providing maximum return on investment.

5. When to Specify Constant Current Strips

While CC strips typically have a slightly higher unit cost, the long-term savings in labor, complexity, and product reliability make them superior for:

- Architectural Cove Lighting: Long, continuous runs where dimming would be immediately visible.

- Retail and Museum Display Cases: Where light quality and color consistency are critical for product presentation.

- Outdoor and Commercial Facades: Applications requiring maximum run length and robust, consistent performance.

6. Partner with the CC Experts for Flawless Execution

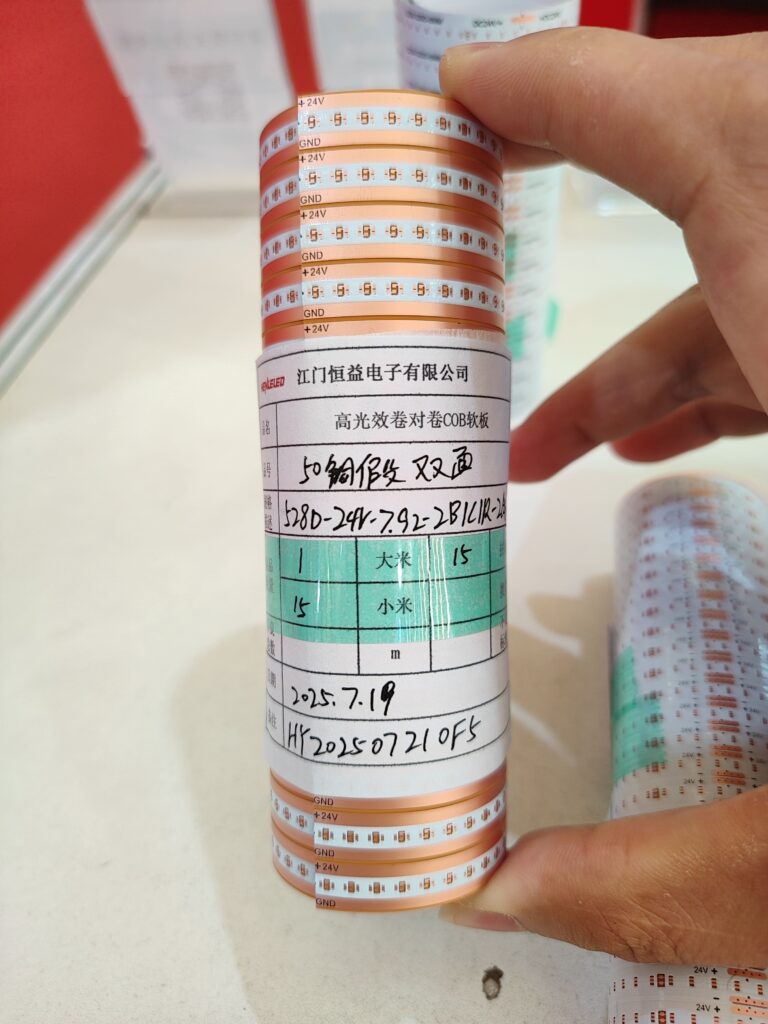

As a manufacturer specializing in high-performance LED solutions, we utilize precision R2R PCB technology to perfectly integrate the necessary Constant Current ICs. Our CC strips are engineered for maximum reliability, giving you the technical edge needed to execute large-scale projects without the headache of voltage drop.

Ready to explore how our Constant Current LED strips can solve your longest lighting challenges? Contact our technical sales team for detailed specifications and customized voltage drop simulation.